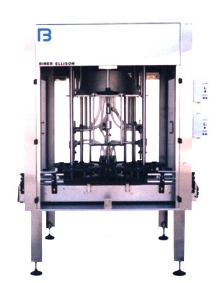

Liquid Filling System accommodates 6 to 36 fill stations.

Press Release Summary:

Economy Rotary Top Drive Filling System is suitable for all free-flowing, non-carbonated liquids including food, beverages, cosmetics, and chemicals. It provides foam control, easy height and fill-level adjustment, and quick-change recirculating nozzle. Power transmission and timing-screw assemblies are positioned on top of machine, keeping important components away from wetted areas.

Economy Rotary Top Drive Filling System is suitable for all free-flowing, non-carbonated liquids including food, beverages, cosmetics, and chemicals. It provides foam control, easy height and fill-level adjustment, and quick-change recirculating nozzle. Power transmission and timing-screw assemblies are positioned on top of machine, keeping important components away from wetted areas.Original Press Release:

BINER ELLISON ECONOMY TOP DRIVE LIQUID FILLERS

LOS ANGELES - The Biner Ellison Economy Rotary Top Drive Filling System is the affordable alternative to in-line liquid filling. This impressive line offers fast, accurate production for all free-flowing, non-carbonated liquids including food, beverage,

cosmetic, chemical, health and beauty aids and much more. The economy line comes equipped with a framework to accommodate from six to thirty-six fill stations depending on your requirements. This liquid filling system provides for fast bottle changeover, accurate fill level, foam control, easy height and fill level adjustment and the Biner Ellison exclusive quick change recirculating nozzle design. This top drive filler uniquely

positions the power transmission for the main turret infeed and outfeed star wheel and timing screw assemblies on "top" of the machine. Precise control and accuracy is achieved by keeping these important components away from wetted areas. Biner Ellison

is a leading manufacturer of precision filling and packaging systems. For more information, please call 323-225-8162 or visit our web site at www.binerellison.com.