New Laser Capabilities Recently Purchased

Weaver & Sons, Inc. is proud to announce the purchase of a new Amada Laser Cutting System.Ã- This new system will not only add greater reliability to our current laser cutting capabilities, but will also add greater speed and automation which we believe will translate into a better value to our customers, says Dyron Overton - President & General Manager.Ã- We have also added robotic...

Read More »EB Industries adds High Power IPG Photonics Laser Capabilities as Part of Its Strategic Growth Plan

EB Industries is pleased to announce that we have recently expanded our capabilities by adding an IPG Photonics YLS-4000Ã- continuous wave Ytterbium fiber laser to our processing line.Ã- The new laser has power ratings fromÃ- 400 w to 4 kW with both continuous wave (CW), and pulsed operating modes.Ã- Included with the acquisition are a number of different fiber’s, weld heads,...

Read More »

CW Low-Moded Laser is designed for thin material spot welding.

Used when welding thin materials or where it is preferred that weld is not visible from back, Low-moded 200 W laser evenly spreads energy overÃ- area toÃ- remove high intensity peak. Beam is tailored to suit application withÃ- appropriate degree of intensity and mode stability, resulting in profile that avoids cratering or break throughs in spot weld. CW orÃ- up to 100 kHz...

Read More »Freudenberg Captures Sustainability Award for Unique Manufacturing Process that Reduces Engineered Waste

•Ã- Ã- Ã- Ã- Proprietary technology wins 2013 Manufacturing Leadership 100 (ML100) Award •Ã- Ã- Ã- Ã- Alternative to stamping will help Freudenberg achieve zero manufacturing waste and achieve its sustainability objectives •Ã- Ã- Ã- Ã- Process is faster, safer and eliminates up to 1,800 tons of scrap steel per machine per year PLYMOUTH,...

Read More »

Next-Gen Nanoparticle Arc Shields

This white paper provides an overview into integrating nanoparticles into Paulson face shields.

Read More »KTI, Inc Expands Its Laser Welding Capability

KTI has expanded its current laser welding capability by adding a state of the art CNC 2 KW Continuous Wave Fiber Laser to its E.Windsor, CT facility. This additional laser welding capacity will broaden our current laser capability and further complement our already strong Electron Beam Welding services, states Eric Welker, VP General Manager. We welcome your inquiries. Our technical staff is...

Read More »Laser Welding for a Wide Range of Parts

Versatile and quick: A wide range of parts can be detected quickly and machined precisely with SCHUNK's PSM 400 laser welding machine. SCHUNK presented its highly flexible laser welding machine for the partially automated deposition welding and repair welding of challenging materials and complex component geometries for the first time at Euromold in Frankfurt. The precision machine allows both...

Read More »

Nd:YAG - Laser Welding Systems

Date: 2-16-09 Process Welding Systems, Inc. (PWS) has partnered with OR Lasertechnology, Inc. to sell their line of laser welders. PWS recently installed an HTS 160 Watt Laser System in our weld lab for use in welding demonstrations, welding development, weld training and contract welding. The HTS 160 features motor traverse in X/Y/Z and R axis, teach-in function, autoweld (CNC control), internal...

Read More »7500 Series FiberStar Fiber Diode Micro-Welding Workstation

7500 Series FiberStar Workstations offer a significant competitive advantage for today's medical device and micro component assembly marketplace. Fiber Diode technology produces a sharp, focused light beam that consistently melts a very small area of metal. The benefit of this technology is that very little heat is generated at the weld point allowing users to easily weld > 0,05mm from the most...

Read More »

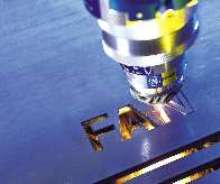

Laser Packages cut and weld machine tools.

Models C5000-E and C6000-E are carbon dioxide laser sources offering 5 kW and 6 kW power. Laser source, CNC, and servomotors are integrated and interfaced as complete system. Laser communicates with CNC via optical bus, and all laser control and diagnostics are integrated into CNC. Historical data for maintenance purposes is logged and can be accessed via CNC screen. Both laser packages can...

Read More »

DoorKing's 1601 Lane Barrier Provides a Higher Level of Traffic Control for Less

DoorKing is proud to introduce an easy add-on to its 1601 Barrier Gate Operator: The 1601 Traffic Lane Barrier. The barrier gate provides greater traffic control while eliminating the need for bollards or crash beams. Check out this video to learn more.

Read More »