TQC Automatic Film Applicator

The TQC Automatic film applicator provides a reliable basis to apply coating films to test charts, panels or foils in a uniform and reproducible way in order to eliminate variations caused by human factors. Variations in speed, pressure and direction of draw down cause irregularities. Other factors that may influence the result are the shear rate and the weight of the applicator. With the TQC...

Read More »

Tandem Printer Applicator combats counterfeiting.

Utilizing 2 in-line thermal print engines, Tandem Label Printer Applicator can print and apply customized anti-counterfeiting labels. Starting with unprinted or pre-printed label stock, first station prints standard product and lot information such as GTIN, serial number, lot code, and expiration date, both in human readable and liner or 2D bar code format. Second print station, utilizing...

Read More »

Printing System automates packing slip/shipping label processes.

While automating packing slip and shipping label printing, folding, stuffing, and applying, FOX IV TwinPrint™ system also ensures shipping address label matches packing slip.Ã- Dual printheadsÃ- produce shipping information andÃ- confidential packing slip onÃ- one label.Ã- Liner is die-cut such that it remains with label and provides protective, secure adhesive perimeter....

Read More »Hot Melt System suits case and carton sealing applications.

Designed for reliability and flexibility, InvisiPac™ Tank-Free™ Hot Melt Delivery System includes vacuum feed system, in-line melt chamber, heated hose, and applicator. Tank-free design minimizes time adhesives spend at high temperatures, reducing char and nozzle plugging, eliminating need for scraping, and lowering maintenance requirements. Start-up times are ~10 min or less, andÃ- areas...

Read More »

Retem System: Breakthrough Technology in Soil Stabilization & Erosion Control

This white paper provides an overview of Retem Systems breakthrough technology.

Read More »Heat Transfer Decorating Machine applies graphics to cylinders.

Using combination of heat, pressure, and dwell, Transgrafix HTÃ- applies pre-printed, full colorÃ- graphics permanently toÃ- cylindrical parts. Platform utilizes silicone rubber roller mounted to vertical stamping head for peripheral marking, and ability to combine full color decoration with metallics can be accomplished in one pass.

Read More »

Power Adhesives Introduces Hot Melt Adhesive for Faster, Easier and More Efficient Bonding of Precast Concrete Forms

CHARLOTTE, N.C. - A hot melt adhesive system that's perfect for bonding reveal, chamfer, form liners, weld plates and structural and other architectural elements in all types of pre-cast concrete form is now available from Power Adhesives. Easier, faster and more cost-efficient than any other adhesive type system in the industry, the new Power Adhesive hot melt system consists of a line of...

Read More »Hot Melt Adhesive Dispensing Applicators have fast, slim design.

Featuring 2 msec cycle times and 18 mm slim body configuration, MiniBlue II utilizes combination of module and solenoid technology which lends to extended service life, greater productivity, and minimized maintenance/downtime. Ball-and-seat design enhances adhesive cutoff at higher speeds while also promoting consistent, repeatable adhesive patterns as well as shorter beads at higher line speeds....

Read More »

Printer Applicator unites packing slip and shipping label.

Equipped with 2 printheads, Uniwall Series TwinPrint Printer Applicator prints and applies both shipping label information and packing slip information on single label. Applicator is mounted above conveyor and prints and applies shipping label/packing slip to top of cartons at speeds up to 25 cartons/min. System comes standard with 16 in. OD label roll, dynamic tension control, positive-pressure...

Read More »

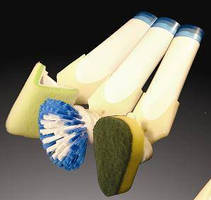

HandsFree Applicator Tubes Introduces Tube Tools

Tube Tools are now available to create an all in one squeezable tube device for industrial, personal care and cosmetic applications. It's a plastic part that simply attaches to the sealed end of a filled tube that can be scaled up or down in size to fit any tube in the world. You can create a platform with an applicator, bristol brush, comb, scraper, personal shaver or anything that compliments...

Read More »Applicator Guns suit flat panel gluing applications.

Featuring FP-900 swirl gun, RhinoÃ-® pump, hose, and suspension package, FP-900 Handguns facilitate manual application of ambient-temperature, moisture-cure adhesives in horizontal or vertical flat panel processes. Guns offer 360Ã-

Read More »

General Pipe Cleaners Presents Lightweight, Powerful JM-1000 Mini-Jet

The lightweight, compact JM-1000 Mini-Jet clears grease, sand, and ice with a high pressure water jet.

Read More »