Moyno, Inc.

Springfield, OH 45501-0960

Progressive Cavity Pump handles high solids.

System 2000 HS utilizes Ultra-Feeds rotor technology and twin-screw feeder, which enable system to handle high percentage of semi-dry, high solids content material. Twin screw feeder includes 2 self-cleaning, intermeshing feed screws that supply constant, pressurized feed rate to system's G4 Progressing Cavity Pump. System is suited for dewatered sludge transfer in municipal and industrial...

Read More »

Mechanical Seal handles highly viscous applications.

Power Seal(TM), used on PowerFlow pump systems, withstands operating conditions with temperatures up to 350Ã-

Read More »

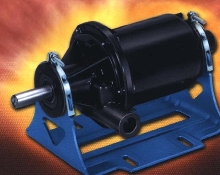

Process Pump handles heavy-duty applications.

Suited for highly viscous, abrasive, and corrosive applications as well as thin, water-like liquids, PowerFlow pump utilizes hardened tool steel or hardened 17-4 PH stainless steel pumping elements. Metal stator enables unit to handle fluids with temperatures up to 500Ã-

Read More »

Sanitary Pump meets 3A standards.

MoynoÃ-® 500 Sanitary Pump, made of food-grade 316 stainless steel, features elastomers that satisfy FDA requirements as well as Quick Disassembly Clamp that simplifies pump disassembly and cleaning. With repeatable, non-pulsating flow, product handles pressures to 150 psi, flow rates from .5-15 gpm, and fluid temperatures to 210Ã-

Read More »

Progressing Cavity Pump handles caked materials.

Series 2000 Model G3 passes particles up to 1.5 in. in diameter and handles fluid viscosities up to 1,000,000 cps unassisted. It offers flow rates to 400 gpm and pressure capabilities to 350 psi. Bridge breaker device prevents accumulation of material in throat of pump and is driven by pump motor, eliminating additional power supply. Crown gear-type universal joint accommodates high torsional and...

Read More »

Stator Removal Tool facilitates pump maintenance.

Stator Removal Device is designed to be portable within plant facility and is for use at either pump location or in maintenance shop. It enables single maintenance person to remove and replace large stators and rotors, minimizing downtime. Tool is compatible with company's medium to large pumps and pump stators.

Read More »

Progressing Cavity Pumps suit material transfer applications.

Offered with mechanical seals, MoynoÃ-® 500 Series 200 Motorized Pumps are capable of handling clean, clear liquids as well as abrasive and corrosive fluids. Design incorporates fully-molded wobble stator and dual, heavy-duty ball bearings (fully sealed). Self-priming pumps are equipped with non-pulsating, low-shear flow, which remains steady under variations in suction head. Flow rates are...

Read More »

Grinder Pumps suit spills, clean-up, and fluid transfer.

Series 400 pumps offer designs that combine solids reduction unit with progressing cavity pump. Replaceable carbide tips on cast iron cutter disc rotate against stationary, hardened tool-steel cutter ring. Stringy fibers and debris are reduced to consistent particle sizes. Pumps include molded, elastomeric wobble stator; flow rates to 15 gpm; discharge pressures to 100 psi; prelubricated, fully...

Read More »

Progressing Cavity Pump offers open throat configuration.

MoynoÃ-® 1000 pump, equipped with large suction hopper, transfers viscous materials from its auger assembly to rotor-stator pumping elements. It offers hardened, sealed, and lubricated, pin-type universal joints; flow rates to 325 gpm; and pressure capabilities to 225 psi. Able to pass particles up to 1.1 in. in diameter, pump offers abrasion resistance and volumetric and mechanical...

Read More »

Positive Displacement Pump handles wide range of fluids.

Model 301 Series Progressing Cavity Pump handles applications from clean, clear liquids to abrasive fluids. It pumps at flow rates to 13 gpm at discharge pressures up to 25 psi. Pump has phenolic housing and rotor, making it suited for corrosive chemicals. Reverse covered seal between rotor and shaft eliminates metal exposure to fluids. Resilient cushion and cradle mounting on self-priming pump...

Read More »