Moyno, Inc.

Springfield, OH 45501-0960

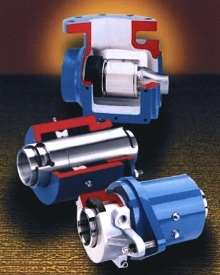

Progressing Cavity Pumps work in many applications.

Model 2000 pumps are available in variety of construction materials to handle applications from shear-sensitive liquids to process slurries and sludges. Options include: Flush Gland that allows packing leakage to be flushed away from pump, preventing damage to seals and packing; Fiber Deflector, which prevents ragging around rotating shafts when stringy materials are present; and Shaft Sleeve,...

Read More »

Pump Feeder handles high viscosity pumped materials.

AugMentor(R) Pump Stuffer is electrically driven and handles materials in excess of 1,000,000 cps. It features 300 series stainless steel construction and No.4 polished finish for corrosion resistance and clean sanitary surfaces. Slow-speed, bottom-drive auger results in low product shear with minimal product smearing. Hinged hopper makes cleaning and inspection hassle-free.

Read More »

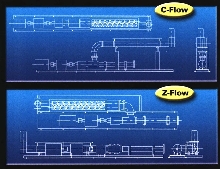

Pump System offers various configurations.

2000 HS System, designed for transferring dewatered sludge in municipal wastewater treatment, features integral hopper with twin-screw auger feeder and Model 2000 G4 progressing cavity pump for handling semi-dry, high solids content material. Feeder supplies constant pressurized feed rate to pump resulting in 100% pump cavity fill rate. Configurations include: C-Flow, S-Flow, T-Flow, U-Flow, and...

Read More »

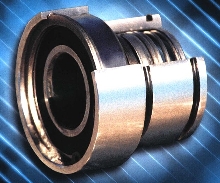

Sanitary Pumps handle abrasive materials.

Sanitary Pumps have standard mechanical seals and meet 3A sanitary standards with no modifications necessary. Close-coupled/open throat design is offered in standard models. Pumps handle solids up to 1 in., and are available with flow rates to 325 gpm and pressures to 225 psi. They are self-priming and suitable for applications where bacteria and contamination must be avoided and/or frequent...

Read More »

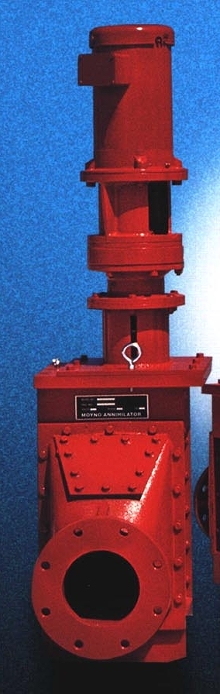

Solids Reduction Unit retrofits to twin shaft grinders.

Annihilator twin shaft solids reduction unit is supplied with seals and bearings housed in replaceable stainless steel cartridge, which allows on-site replacement. Counter-rotating, hexagonal shaft design coupled with hardened steel cutters provide maximum shredding strength necessary to process 300 to 4,250 GPM of influent. Annihilator is fitted with toothed cutting spacers, electronic control...

Read More »

Grinder is available with 3 to 5 hp motors.

Annihilator(TM) solids reduction unit features counter-rotating, hexagonal shaft coupled with 5-tooth, hardened steel cutters to process from 300 to 4,250 gpm of influent. Grinder can prolong service life of downstream equipment such as pumps, sensors, monitors and valves. Seal/bearing cartridge assembly eliminates need to disassemble entire grinder when servicing. Electronic control panel offers...

Read More »