Progressive Cavity Pump handles high solids.

Press Release Summary:

System 2000 HS utilizes Ultra-Feeds rotor technology and twin-screw feeder, which enable system to handle high percentage of semi-dry, high solids content material. Twin screw feeder includes 2 self-cleaning, intermeshing feed screws that supply constant, pressurized feed rate to system's G4 Progressing Cavity Pump. System is suited for dewatered sludge transfer in municipal and industrial wastewater treatment.

System 2000 HS utilizes Ultra-Feeds rotor technology and twin-screw feeder, which enable system to handle high percentage of semi-dry, high solids content material. Twin screw feeder includes 2 self-cleaning, intermeshing feed screws that supply constant, pressurized feed rate to system's G4 Progressing Cavity Pump. System is suited for dewatered sludge transfer in municipal and industrial wastewater treatment.Original Press Release:

Moyno® 2000 HS Systems Handle Higher Percentage of Solids

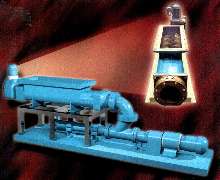

Springfield, OH, USA - The Moyno® 2000 HS System handles a higher percentage of solids than other progressing cavity pumps to minimize processing costs. This system is the cost-effective alternative to expensive, high-maintenance piston pumps, conveyors and competitive progressing cavity pumps for dewatered sludge transfer in municipal and industrial wastewater treatment. It utilizes Moyno's proprietary Ultra-Feeds rotor technology and its advanced design, twin-screw feeder, that enable the system to handle a higher percentage of semi-dry, high solids content material.

The twin screw feeder includes two self-cleaning, intermeshing feed screws that supply a constant, pressurized feed rate to the system's Moyno® G4 Progressing Cavity Pump. The resulting 100% pump cavity fill rate enhances overall system performance and cost efficiency. The twin-screw feeder also eliminates the need for a feed pump or extended augers common to lengthy, competitive, open-throat PC pumps.

Moyno, Inc. is a leading manufacturer and marketer of Moyno progressing cavity pumps, multiphase fluid transfer systems, grinders and controls. It has an extensive worldwide stocking

distribution network that serves a wide range of industries including water and wastewater treatment, pulp and paper, chemical, food, pharmaceutical, mining, petrochemical, and oil and gas recovery. Moyno, Inc. is a unit of Robbins & Myers, Inc.

Reader service inquiries should be forwarded to TDH Marketing & Communications, Inc., 8153 Garnet Drive, Dayton, Ohio, 45458. Phone: 937-438-3434. Fax: 937-438-345.3. E-mail: literature@tdh-marketing.com.