Tooling is manufactured to application requirements.

THINBITÃ-® DESIGN-A-GROOVE(TM) tooling is modified according to user-specific application requirements. Configurations include face grooving geometry, full or corner radius, increased depth of cut, chamfering, chip control, and top rakes. Additional customized geometric combinations are also available, along with specialized toolholders. DESIGN-A-GROOVE(TM) configurations may be provided on...

Read More »

Test Equipment Accessories are ergonomically designed.

SureGrip(TM) test tool accessories provide additional grip to reduce chance of probes slipping from users' hands or off component. Accessories include alligator clips and test leads, with rubber over-molded surfaces and finger-hugging curves for comfort and operational ease. All 11 accessories carry 1,000 V Category III/600 V Category IV safety ratings, making them safe for use in plant MRO,...

Read More »End of arm device suits finishing applications.

UltiBurr 630, equipped with 0.88 hp quiet air motor, performs burr removal and polishing operations on metals and plastics. Robot program continuously varies compliance force applied to workpiece by changing air pressure to tool's compliance unit, allowing for automated changes in application characteristics. Variably-compliant end-of-arm device is compliant in all three dimensions (x, y, and z),...

Read More »

Accessory Tower makes use of vertical workspace.

Accessory Tower mounts to flat, horizontal area such as laminate or wood work surface. It is made of 12 ga steel and extends 48 in. above surface. Perpendicular horizontal channel is 24 in. long and supports up to 2 suspended tools. Tower Parts Bin Panel and Tool Balancer can be attached for easy access and usage of tools and hardware. Tower makes use of vertical space to help production...

Read More »

Glass Fabrication for MEMS Applications

Micro-electromechanical systems (MEMS) can be found in nearly every industry, such as the consumer electronics and semiconductor fields. Learn more about the technology and its applications.

Read More »

Tooling fabricates interlocking sheet metal assemblies.

SnapLock(TM) lance and form tooling produces self-locking, spring loaded tabs that snap securely into pre-punched holes. Small button in top of form is semi-sheared to provide positive mechanical lock when engaged with hole in receiving tab. Tab and hole design locks two components securely together without need for welding or additional assembly. Dissimilar materials such as stainless steel and...

Read More »

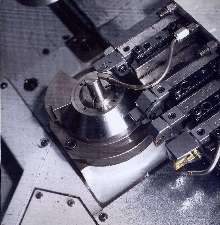

Tooling suits integrated turning and milling machines.

Equipped with Kenclamp clamping system, KM tooling delivers 3-surface contact. Quick-change tooling system consists of spindle with built-in KM connection that accepts KM toolholder or cutting unit using face and taper contact between spindle and toolholder. Machine-specific adaptors make it possible to utilize full line of existing KM turning tools on any machine. Line includes collet and...

Read More »

Tooling System accommodates Swiss-style machines.

KM Micro quick-change tooling system reduces time required to change inserts from 5 min to 30 sec. Based on KM quick-change tooling design, system consists of 1 clamping unit attached to gang plate. Clamping unit locks toolholder that uses coincidental cone arrangement to provide 3-point contact between clamping unit and toolholder. Clamping units are available to fit 12 and 16 mm and 1/2 and 5/8...

Read More »

Tooling Tables suit a wide range of VMCs.

Tsudakoma TN Series Rotary Tables offer clamp torque up to 625 lbs-ft and indexing speeds of 44 rpm (rotating axis) and 22 rpm (tilting axis). They require no hydraulics and offer maximum machine flexibility. Options include inductosyn scales, pneumatic rotary joint, and a pull stud device for automatic loading and loading a workpiece.

Read More »Steel Turning Grades improve tool life.

KC9110 is an ISO class P10 grade designed for finishing operations while KC9125 is a P25 class grade designed for universal machining on all types of steel. Both feature 3 main layers and several sub-layers of coating with total thickness of 18 microns. Main coating layers include: medium temperature titanium carbonitride (TiCN), fine-grain alpha structure aluminum oxide (Al2O3), and thin layer...

Read More »

Machining Center accommodates parts/castings to 441 lbs.

Model TC-22A, 30-taper machining center incorporates column and base designed from CAE analysis and DBB spindle construction. Machine drills, taps, and mills with spindle speeds up to 12,000 rpm and traverse speeds of 2,205 ipm on all axes. Its double arm ATC mechanism system keeps tool changes to 1.8 seconds. Controller, usable with G-code, also includes non-stop tool change code. Conversational...

Read More »

The Carbontec System: A Smarter Way to Heat Your Buildings

Carbontec's paper-thin radiant heating systems reduce energy consumption costs by warming the building surfaces instead of controlling air temperature. Check out our video to learn more.

Read More »