Roughness Tester integrates into material handing processes.

SurftestÃ-® SV-3000 lets users integrate CNC surface roughness measurement into automated material handling and downstream machining and assembly processes. System software supports RS-232C for bi-directional communications between its PC and PLCs of material handling systems. Product offers cabinet enclosures with required safety interlocks and indicators, while FORMTRACEPAKÃ-® software...

Read More »

Surface Roughness Tester accommodates heavy workpieces.

Engineered around column-moving mechanism, CNC SurftestÃ-® SV-800 is constructed to attenuate vibration and minimize measurement deviations. Measuring envelope of 800 x 500 x 200 mm and probe arm accommodate workpieces such as crankshafts and camshafts as well as other powertrain, engine, and similar components. Probe arm also enables unit to measure multiple cross sections and waviness. With...

Read More »3D Surface Gauge does not cause surface damage/defects.

CMMaster(TM) 3D Optical Surface Gauge combines moirÃ-© imaging technology with proprietary software algorithms to create 3D surface measurement system. Non-contact surface contour gauge provides measurements with 0.001 in. or better resolution, and results can be compared to CAD and CMM data. Optical system can measure areas larger than 3 ft in dia in one view, while full field imaging...

Read More »

Thread Gages are suited for deep holes.

Able to be used at depths that exceed hole diameter, Multi-Ball(TM) products inspect screw threads for size, location, concentricity, or runout. Thread micrometer measures size, taper, and out-of-roundness of threaded holes for most sizes up to 1 in. dia. Location gage determines location/orientation of threaded hole axis using expanding pattern of balls that come into contact with thread flanks...

Read More »

A True Game-Changer For Walk-In Unit Frame Performance

This white paper outlines the eight reasons why the FUSIONFRAME system is the superior thermal envelope system. Download now to find out more.

Read More »

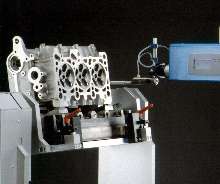

Gaging Fixtures measure difficult surfaces in seconds.

MarSurf(TM) Fixtures measure automotive component surfaces right on shop floor. Five units measure cylinder walls, thrust faces on journals and crankshafts, standard bore surfaces, deep bore surfaces, and deck faces on blocks and cylinder heads. Built as modular series keyed to requirements of each component, fixtures automatically position gage probe and enable operators to complete entire...

Read More »

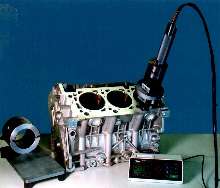

Roughness Measuring System suits automotive applications.

Automotive Roughness Measuring System consists of part-specific holding fixture mounted to granite plate, and measuring head with user-selectable measuring stylus mounted to traveling vertical column. Totally automated, CNC system checks and verifies surface roughness and contours of internal engine components. It provides detailed measurement reports to document part quality and allow immediate...

Read More »

Measuring System analyzes contour and surface roughness.

FormtracerÃ-® CS-Series generates contour and surface roughness analysis from single measurement of workpiece. Model CS-3000, for smaller workpieces, offers max measuring range of 10 mm and max resolution of 0.8 nm. Model CS-5000 provides laboratory level accuracy, employing Laser Holoscale(TM), which utilizes interference of diffracted light to achieve nanometer resolution. Formtracepak...

Read More »

Gages simplify threaded hole inspection.

Multi-Ball(TM) thread-inspection products allow hardened balls to be used as thread-flank contact elements. Free-floating balls can be positioned at any location on thread. Turning of knurled thimble or pin expands balls into contact with thread flanks. Multi-Ball(TM) micrometers measure size, taper, and out-of-roundness of threaded holes. Multi-Ball(TM) location gages determine location and...

Read More »

Surface Finish Gage speeds crankshaft measurements.

Model 1000 has 3 variable reluctance pickups, each having 5Ã-µm diamond stylus that measure roughness parameters such as Ra, Rp, Tp, and Rsk on main and rod journals as well as thrust faces. Manually loaded, fully automatic gage utilizes Windows NT software graphics and may be stored and used in SPC programs. Capable of scanning 2,000 points/mm, gage measures entire length of journal in 1...

Read More »

Gage measures contour and roughness in one stroke.

With traversing length of up to 4.72 in., MarSurf(TM) LD 120 utilizes single drive unit and laser interferometer. System includes PC with data acquisition card and menu-driven, Windows-based software. Using triangular support design, LD 120 incorporates tracing arm with .394 in. range and magnetic tracing arm mounts. It uses 2 Ã-µm (80 Ã-µin.) radius diamond stylus tip and provides ratio...

Read More »

DoorKing's 1601 Lane Barrier Provides a Higher Level of Traffic Control for Less

DoorKing is proud to introduce an easy add-on to its 1601 Barrier Gate Operator: The 1601 Traffic Lane Barrier. The barrier gate provides greater traffic control while eliminating the need for bollards or crash beams. Check out this video to learn more.

Read More »