Industrial Pass Through Washer targets hard-to-clean applications.

Along withÃ- 12 x 12 in. washer zone onÃ- chain mesh belt conveyor, CBW1212-B features two 20 hp, reservoir-mounted, vertical centrifugal pumps with 260 gpm capacity at 110 lb/in.Ã-² pressure. Belt flow speeds are adjustable from 2–34 fpm, natural gas burner produces temperatures from 170Ã-

Read More »

Robotic Nozzle Cleaning Station reduces integration efforts.

With digital Ethernet communications, TOUGH GUN™ TT3E Reamer fosters integration into digital controls infrastructure. Design eliminates need for analog switch, which also reduces cabling requirements and reduces potential failure points. Also included, remote monitoring capabilities let companies oversee and troubleshoot I/O of each reamer function and its allowable parameters in real-time and...

Read More »HEPA Filtered Hazmat Vacuum increases workplace safety.

Safe-Pak™ collection unit facilitates collection, containment, and disposal of hazardous materials, including potent compounds. Design and functionality eliminates possibility of contamination of cleanroom vacuum or facility and thereby increases worker safety. With enclosed HEPA filter, self-contained unit safely isolates hazardous materials without contaminating cleanroom vacuum. When full,...

Read More »

Ultrasonic Cleaning System employs modular design concept.

ModulesÃ- for Modular AquariusÃ-® plug-and-play,Ã- multi-tank cleaning system can be integrated together to offer maximum flexibility to end-user; wash and rinse stages can be mixedÃ- and matched to provide cleaning system required for application at hand. For 360Ã-

Read More »

How EDM Controls Ensure Aerospace Validated Processes

Download this white paper to learn more about how wire EDM systems are used to validate aerospace manufacturing processes.

Read More »QuantumClean-® and ChemTrace-® to Exhibit at SEMICON Korea 2014

Global Leader in Semiconductor High Purity Process Parts Cleaning, Performance Coatings and Microcontamination Analytical Laboratory Services™ to exhibit at SEMICON Korea 2014 tradeshow. QUAKERTOWN, Pa. - QuantumCleanÃ-® and ChemTraceÃ-® today announced that they will be exhibiting at the SEMICON Korea tradeshow, held at the Coex in Seoul, South Korea from February 12(th) through...

Read More »

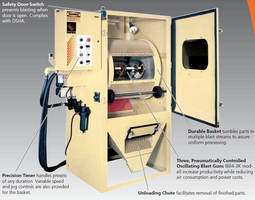

Three Key Benefits for Basket Blasters

Empire's BB2 and BB4 Basket Blasters automate cleaning, peening and finishing of small work-pieces. With certain types of parts, no other finishing method can compare to these heavy-duty production machines in terms of speed and quality results. Typical applications are for parts or items that may be rusty, or in need of cleaning, or where you need to achieve a required surface finish for...

Read More »

Solvent-Based Cleaning Systems can be adapted to task.

Running on halogenated hydrocarbons as well as modified alcohols, Ecoclean Systems combine heat recovery, bypass filtration, injection flood washing, and emission-reducing features. Strong pumps and large-diameter piping permit rapid filling and draining of work chamber and tanksÃ- while ensuring optimum solvent supply to basket. Vacuum technology, with final pressure under 1 mbar,...

Read More »

Aqueous Cleaning Systems from Turbex

Basket and jets move independently Turbex will present at MACH its newest agency line of aqueous cleaning machines from the German manufacturer, MAFAC. Intended for high precision cleaning applications, the equipment uses a world-patented system whereby the movements of the holding basket and spray jets are individually adjustable, allowing them to rotate in the same or opposite directions. Each...

Read More »Elmasonic Ultrasonic Cleaner

Tovatech is pleased to announce a special offer on their top selling Elma Ultrasonic Cleaners. The Elmasonic S ultrasonic cleaner operates in 3 modes: Sweep, Degas, and Normal. Cleaning is optimized in Sweep mode. Sweep guarantees a homogeneous sound field by continuously shifting the sound field maxima. Fresh cleaning liquid does not clean efficiently until fully degassed, as dissolved gas...

Read More »

Carl Zeiss Partners with Lions Clubs International Foundation

Carl Zeiss, a leading provider of optical solutions, is branding a lens and screen cleaning kit for the Lions Clubs International Foundation, the official charitable foundation of Lions Clubs International, the world's largest service club organization. The kits include ZEISS lens cleaning solution, ZEISS lens cleaning cloth, ZEISS pre-moistened towelettes and informational material about...

Read More »

Vector® Sports Training Ball Offers Visible Point of Contact

Our goal is to help every athlete derive maximum enjoyment from their sport and become a better player. We offer a line of innovative training tools that combine cutting-edge technology and out of the box thinking to deliver an unbeatable competitive advantage. The Vector® Sports Training Ball is just another example of our commitment to innovation. To learn how the Vector® is helping ballplayers everywhere, see our video.

Read More »