DMI Event to Highlight Mazak Innovations that Boost Job Shop Efficiency

FLORENCE, Ky.,Ã- – Mazak distributor Dependable Machine Inc. (DMI) will host an open house at its new technology center in Hayden, Idaho, May 10-12 from 10:00 a.m. – 4:00 p.m. (PDT). The event will feature Mazak technologies that simplify part production processes as well as enhance shop floor productivity and versatility. A must-see for attendees will be Mazak’s MAZATROL SmoothX CNC....

Read More »

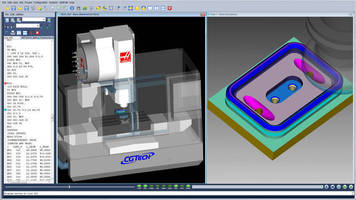

VERICUT Helps Grade Turning and Milling SkillsUSA/NIMS Contest Submissions

Irvine, CAÃ- - CGTech will be on hand at the National Leadership and Skills Conference (NLSC), June 21-23, 2016, to help grade multiple SkillsUSA/NIMS events related to Computer Numeric Control (CNC) machining. CGTech will also be exhibiting its latest version of VERICUT software in Booth S149. More than 16,000 peopleÃ- - including students, teachers and business partnersÃ- - will be...

Read More »

Bronze Wear Plate Manufacturer's Investment in State-Of-The-Art Machining Center Improves More Than Just Capacity

Roseville, MI — National Bronze Mfg. Co., a leading manufacturer of bronze bushings, wear plates, and other machined components, is pleased to announce the completion of their latest machinery addition.Ã- Last year we saw the 103 year old company expanding their high volume bushing production capacity with the purchase of an Okuma CNC turning center and automatic bar feeder.Ã- This...

Read More »

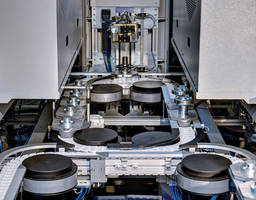

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

Bearing Solutions For Recreational Applications

This white paper provides and overview of bearing solutions for recreational applications.

Read More »

Big-Bore Turning Centers are designed for accuracy and stability.

Models ST-25, ST-25Y (with Y-axis), ST-35, ST-35Y (with Y-axis), ST-45, and ST-45L (long-bed) offer max capacities from 12 x 21 in.Ã- to 25.5 x 80 in. Standard features includeÃ- rigid tapping,Ã- 15 in.Ã- color LCD monitor, and USB connectivity.Ã- Each spindle head has symmetrical design for thermal stability and rigidity, and 45Ã-

Read More »

Hurco to Launch Nine New Machines Plus Software Enhancements

As MACH 2014 is the first national machine tool exhibition in the UK since Hurco redesigned its entire range of machining centres and lathes, every model on show in Birmingham will be new. The company will demonstrate six machining centres and two CNC lathes sporting the latest logo and livery, plus a representative model from its agency range of high-speed machining centres manufactured by...

Read More »

Mazak Midwest Event to Showcase Total Manufacturing Solutions

Attendees to discover new tools and techniques for staying ahead of the manufacturing curveÃ- FLORENCE, Ky. – Mazak invites manufacturers to its DISCOVER MORE WITH MAZAK Midwest event, taking place March 25 – 27 from 9 a.m. to 6 p.m. at the company's Technology Center in Schaumburg, Ill. The event will focus on ways to boost production efficiency through total manufacturing solutions,...

Read More »

Prefabricated Automated Cell provides lights-out production.

In addition to 5-axis vertical machining center, Vertical Center Nexus Compact incorporates standalone Fanuc LRMate 6-axis robot and palletizer system for automated processing of up to 72 individual workpieces measuring up to 3.9 x 3.9 x 3.9 in. Three linear axes attain rapid traverse rates of 1,417 ipm and feedrates of 315 ipm, while 12,000 rpm, 25 hp, CAT 40 spindle provides aggressive...

Read More »

Quicktech TTS-42/ TTS-60 9-Axis Twin Spindle Multi-Tasking Center with B Axis at PMTS in Booth #655

[LORAIN, OHÃ- - FEBRUARY 2013]Ã- Absolute Machine Tools will exhibit the Quicktech TTS-42/TTS-60 9-axis twin spindle multi-tasking turning center at PMTS in booth #655. The high precision, high production CNC bar processing center enables complete part machining including milling of complex features. Available in both 42mm and 60mm (1.65 or 2.36 ) bar capacities as the TTS-42 or TTS-60,...

Read More »

Siemens and Biglia Offer Full Flexibility in New Quattro Series of Turning Centers

Highlights include two-sided machining and servo drive technology Recently, Northern Italian machine tool manufacturer Biglia introduced its multi-functional turning centers of the 'Quattro' series with the Sinumerik 840D sl CNC. The mechanical concept, together with the scalable control, provides users with the most diverse standard turning and milling operations.Ã- The result is increased...

Read More »

Clear Clogged Drains Faster with General Pipe Cleaners' Kinetic Water Ram

The Kinetic Water Ram by General Pipe Cleaners clears out clogged pipes quickly using kinetic energy. The Ram is so simple to operate, anyone can use it. Check out the video to learn more.

Read More »