Davis-Standard to Exhibit Extruder Versatility at NPE

March 18, 2009 (Pawcatuck, Conn.)--Davis-Standard, LLC will exhibit three of its most versatile extruder models with improved control technology during NPE. The extruders on display include a 2 -½-inch (60mm) Super Blue-® with a DS-eTPC touch-panel control system, an HPE-150A and HPE-125H. The DS-eTPC provides a touch-panel solution to replace discrete temperature controllers, temperature...

Read More »Roll Stand System offers multiple extrusion capabilities.

At 40 in. wide, XP ExpressÃ-® is offered with technology for producing sheet with hundreds of layers. It can be equipped with coextrusion die, feedblock, and layer multiplier as well as special adaptor piece for injecting atmospheric gas for foam applications. XP Express PS (packaging sheet) and CS (custom sheet) models are available for in-line thermoforming of PP, APET, and PS and may also...

Read More »

Extrusion Tooling is used to manufacture large wall piping.

Featuring combined die and reservoir system that promotes even material distribution and product consistency, Model 2030 eliminates extrusion issues associated with inconsistent material flow during manufacture of large wall piping (4-20 in. dia) used for oil, gas, and water applications. Co-extrusion capability enables simultaneous extrusion of multi-materials or multi-stripes, and flow analysis...

Read More »

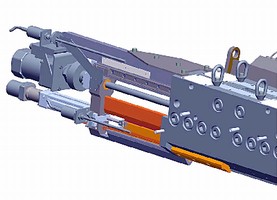

Motorized Dual Deckle automates width changes.

Featuring spring-loaded external segment, Motorized Dual Deckle minimizes or eliminates manual adjustment. It combines internal deckle, which blocks flow with blades from manifold to die lips, and external deckle, which seals off die gap from outside. AC motor drives external deckle and primary internal deckle as single unit, while smaller motor drives secondary internal deckle that fine-tunes...

Read More »Converting Services 101: Types of Services, Applications, and How to Select a Provider

This ebook provides an in-depth guide to converting services.

Read More »

Wayne Machine Delivers New Extrusion Film Technology to AAPPI

TOTOWA, NJ - Wayne Machine & Die Company has designed, built and sold a combination 5-LAYER YELLOW JACKET LABORATORY BLOWN AND CAST FILM LINE to the Advanced and Applied Polymer Processing Institute in Danville, Virginia. This system is based upon new Yellow Jacket die technology that is capable of producing 5 layer blown and cast plastic film in A-B-C-B-A and other configurations. The line can...

Read More »

Rexam Adds Five Davis-Standard Extruders to Union, Mo. Plant

Pawcatuck, Conn.)--Rexam, a world leader in consumer packaging solutions, recently installed five Davis-Standard Thermatic-® extruders at its plant in Union, Missouri. The extruders, ranging in size from 2 inches (50mm) to 130mm, included screen changers, melt pumps and control systems. Rexam, a Davis-Standard customer for 20 years, has purchased 15 Thermatic extruders over the past four years...

Read More »Akron Milacron PAK 350 Single-Screw Extruders Offer Affordable 'Plug And Play' Customization for a Wide Range of Profile Applications

Packaged, quick-install 3.5 extruder runs strong and long with 100 hp DC drive, bi-metallic barrel, and flame-hardened, chrome-plated screws April 2006 - Hard-working and affordable answer machines, Akron Milacron PAK 350 single-screw extruders combine quick plug and play installation with custom configuration to specific applications, then run long and strong with 100 hp DC drive, bi-metallic...

Read More »

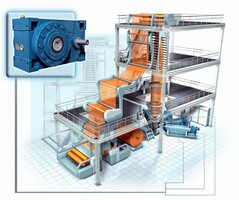

PIV Drives: Single Screw Extruder Drives for Biggest Film Production Line Made by Reifenhäuser

PIV Drives supplied single screw extruder drives for a 35 m high blown film line, that was installed in Spain One of the many applications for blow film lines are agricultural films, that are used in modern cultivation systems to increase yields by covering vast areas of agricultural regions. For this purpose single- and multi-layer wide films are produced on blow film lines. ReifenhÃ-¤user,...

Read More »Dual Downstream Extrusion Lines

Fuelled by a robust market for polymer-based window and fencing components (e.g., window frames, fencing panels) and working on the premise that high-throughput extruders (2000 lb/hr) often run at rates far below their capacity, CDS Inc. in Lachine, Que., recently developed and commercialized a dual post-extruder system for extrusion processors in the Fenestration industries. The system, branded...

Read More »Extruding Machine can form PP, HDPE, and LLDPE flat yarn.

Along with computer-controlled frequency conversion, FYF-SPL series flat yarn extruders adopt electric digital-simulation control technology such as speed regulation and controllable silicon direct current speed regulation. Assembly offers advanced band net change structure as well as fibrosis structure used for producing flexographic packing bags or fibrosis bag sewing thread. Stock thread...

Read More »

New Davenport Hybrid Machine Offers Unique Flexibility for Parts Manufacturing

The Davenport Hybrid machine offers greater flexibility, easier set-ups, and faster cycle times. Check out the video to learn more.

Read More »