Motorized Dual Deckle automates width changes.

Share:

Press Release Summary:

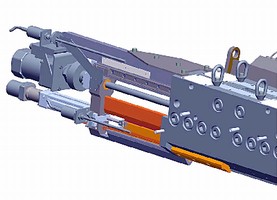

Featuring spring-loaded external segment, Motorized Dual Deckle minimizes or eliminates manual adjustment. It combines internal deckle, which blocks flow with blades from manifold to die lips, and external deckle, which seals off die gap from outside. AC motor drives external deckle and primary internal deckle as single unit, while smaller motor drives secondary internal deckle that fine-tunes flow at either end of die, minimizing formation of edge bead.

Original Press Release:

Motorized Dual Deckle for Extrusion Coating Automates Width Changes and Reduces Downtime Between Coating Jobs

Spring-Loaded External Segment Reduces or Eliminates Need to Tighten Seal

CHIPPEWA FALLS, WI, U.S.A., June 29, 2007: A motorized dual deckle with a spring-loaded external segment enables extrusion coating processors to automate width changes, increase the precision of deckle settings, reduce or eliminate manual adjustment, and cut downtime between job changeovers, it was announced today by Extrusion Dies Industries, LLC (EDI). The company will introduce the concept at K 2007 (Stand 02/G06).

The new deckle incorporates two innovations:

Motorized drives with built-in edge bead control. An AC motor drives the external deckle and the primary internal deckle as a single unit, while a smaller motor drives a secondary internal deckle that fine-tunes the flow at either end of the die, minimizing the formation of edge bead. Besides reducing the time needed to change width settings, motorization makes it possible to run the deckle as part of a computerized processing system.

Spring-loaded external deckle. With standard external deckles, operators needed to loosen and tighten fasteners for every change in product width. EDI has replaced this system with a spring-loaded device that provides constant pressure at the lips of the die while permitting width changes with little or no manual adjustment.

Motorizing and automating the process of changing width enables extrusion coating processors to return to exactly the same deckle settings every time they run a particular product, said Jeff Seckora, product manager. Besides helping to make this automation possible, the spring-loaded external device goes a long way toward EDI ultimate goal of transforming width variation into a hands-free operation.

Dual Deckles Combine the Benefits of External and Internal Devices

A deckle is a mechanism that varies product width by blocking off portions of the flow at either end of a flat die. Dual deckles combine an internal deckle (which blocks flow with blades from the manifold to the die lips) and an external deckle (a wedge-shaped device which seals off the die gap from outside). Because the deckles are linked to the same drive, they function as one system. In addition, they substantially reduce polymer leakage from the die.

External deckles provide more effective seals but create stagnant areas behind the deckle barrier and tend to promote the formation of relatively large edge beads along either edge of the coating. The bead must be trimmed away as scrap, wasting polymer and substrate.

Internal deckles completely seal off the ends of the internal flow channels of the die, eliminating areas of stagnation. In addition, because the deckle actually consists of independently adjustable blades, it can be used to fine-tune the edge profile of the polymer flow as it exits the die, minimizing edge bead formation.

Extrusion Dies Industries, LLC is a leading international supplier of flat dies for sheet, film, extrusion coating, slot die coating, and pelletizing. The company designs and manufactures dies, feedblocks, deckling systems, vacuum boxes, and related equipment. Its subsidiaries include EDI GmbH in Reichshof-Wehnrath, Germany, and EDI China in Shanghai. In the U.S.A., Germany, and China, EDI operates facilities dedicated to reworking its own dies and those built by other suppliers, and it has licensed a fourth rework facility in Japan. Headquartered in Chippewa Falls, Wisconsin, U.S.A., EDI sells half of its dies outside the United States. Visit www.extrusiondies.com and www.reworkdies.com. E-mail: sales@extrusiondies.com.

Robert J. Martino

Martino Communications Inc.

8 Main Street / P.O. Box 379

Hastings-on-Hudson, NY 10706 U.S.A.

Tel: 1-914-478-0754

Fax: 1-914-478-0959

Email: bob@martinocommunications.com

Visit www.martinocommunications.com