Astro Machine Works Introduces Our New EDM Capabilities

What better way to start the year than with new electrical discharge machining services (EDM) to add to our already long list of capabilities? How else to bolster our EDM offerings than adding the newest and latest in machines? With the introduction of the Sodick AQ5371 Wire EDM machine, Astro Machine is doing just that. As EDM work has only been a service we have worked with for the past twelve...

Read More »

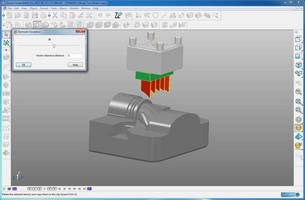

Delcam Supports all Leading EDM Equipment with Integrated Electrode Solution

Delcam has extended the range of EDM equipment supported by its integrated solution for the design, machining and inspection of electrodes. Delcam Electrode can now provide scripts for all the leading manufacturers, including AgieCharmilles (Agievision and CT Millennium controls), Makino EDM, Mitsubishi Electric, ONA EDM, OPS-Ingersoll, Sodick and Zimmer & Kreim. Full details are available on the...

Read More »

Mitsubishi Showcases Complementary Technologies at Eastec Booth #1116

Wood Dale, IL - Mitsubishi announces its extensive lineup of complementary technologies to be showcased at Eastec booth #1116. Mitsubishi will highlight the latest in wire EDM, sinker EDM, hole popper and waterjet technologies. The FA10S Advance wire EDM features the M700 Series Mitsubishi control. This Windows-based system with 15-inch LCD touch screen display provides a simple menu...

Read More »

Sodick to Feature High Technology at Eastec in Booth #1205

Sodick Inc., will be featuring its latest innovative technology in Brooks Associates Booth #1205 at Eastec 2011, including the AG40L Sinker EDM and the AG600L Wire EDM. The AG40L Sinker EDM features high speed and high acceleration linear motor drives, this enables even and natural flushing condition that leads to perfect part accuracy. The AG40L can reduce EDMing time by as much as 50%. The...

Read More »

Peristaltic Pump Vs. i-FILL® Technology

Intellitech's advanced i-FILL® pumps are used by companies working in some of the world's most demanding sectors, delivering innovative, highly accurate and repeatable results, ensuring ultimate reliability and ease of use for all of our clients.

Read More »Behringer Saws Expands Reach Throughout Canada

Morgantown, PA (April 8, 2009) - Behringer Saws has announced the addition of two new distributors for its products in Canada. Spark & Co of Montreal and Toronto and Can Star Industrial, Ltd., of Edmonton will help the company more effectively cover the entire country east to west in the steel construction, automotive, aerospace and oil and gas industries. Spark & Co is a specialist in high end...

Read More »Mitsubishi Showcases Complementary Technologies at Westec Booth #3532

January 17, 2007 Wood Dale, IL - Mitsubishi announces its extensive lineup of complementary technologies to be showcased at Westec booth #3532. Mitsubishi will highlight the latest EDM, hole popper, waterjet, and high-speed vertical machining equipment. The new FA10 Advance wire EDM features a new M700 Series Mitsubishi control. The Windows-based system with 15-inch LCD touch screen display...

Read More »

Aircraft Engine Simplifying Diffuser Manufacturing and at an Affordable Cost

diffuser- a critical, but difficult to produce shape that spreads the air flow and cools hot section parts. Beaumont Machine, the Innovator in Fast Hole EDM, announces their revolutionary Two-Step Diffuser Process*. Diffuser shapes have become a daunting challenge for aircraft engine OEMs and their suppliers. In most production environments, diffuser shapes are generated on a EDM sinker after a...

Read More »

Wire-Cut EDMs offer high-precision manufacturing.

Vertex 2, 2F, 3, and 3F models feature IPG-V generator, which delivers fine spark gap for optimal part geometry and surface finishes down to 0.05 Ã-µm Ra with no white layer in continuous operation. Vertex 2F is equipped with Agievision 5 control based on Windows XP platform and powered by dual Pentium M processors, 40 GB hard drive, and 512 MB RAM, which provides 3D graphics, real-time...

Read More »New Hampshire Stamping Adds to its Capabilities

Founded in 1991, New Hampshire Stamping Corporation has grown to become a leader in the vast array of metal stamping technologies. With over a decade of experience, we have the knowledge and versatility to meet almost any stamping challenge. NH Stamping has been providing you with quality metal stamping and engineering since 1991. With the purchase in January 2006 of ROBOCUT a-1 iC we now can...

Read More »EDM Machines/VMCs suit surface finishing applications.

Wire EDM Model FA10S features programmable flushing system, fine finish power supply, and non-isolated workpiece table. Sinker EDM Model EA12V includes multi-position work tank, which allows operator to set up while circulating dielectric fluid. ESPER II software offers multiple programs for measuring, power settings for burning, and orbital data for finishing. High-speed Model HC-658 VMC...

Read More »

Do You Have Unique Lifting Needs?

EZRig Cranes offers lifting solutions that are engineered for robust performance, providing the ultimate in portability. Designed for real-world lifting needs, our products are small and light with options and features that make them ideal for a broad range of applications. See our video to learn how an EZRig Crane can simplify your lifting requirements.

Read More »