Screening Station accelerates manufacturing processes.

Bag-dumping/screening station examines bagged materials for lumps and foreign matter before they enter manufacturing processes. Self-contained station includes low-profile separator, hood with vent, heavy-duty bag-support screen, and stand. Optional magnet,built into product discharge, is available.

Read More »

Container Dumper discharges non-free flowing materials.

Container Dumper offers 60 deg discharge angle and 150 deg rotation. Lift and Seal System(TM) hydraulically seals container to pour hood, eliminating dust and product contamination. Unit features tubular carbon steel frame, NEMA 4 electricals, FDA approved white epoxy finish, and 304 stainless steel on all product contact surfaces. Units are designed for any size or weight container with...

Read More »

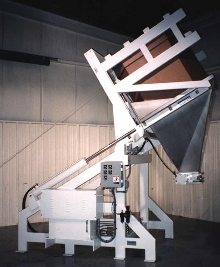

Hydraulic Lifter-Dumper can be used for hazardous operation.

Telescopic container lifter-dumper incorporates tapered chute for dumping powder, liquid, or solid materials. Tilt capability is 135 deg or 45 deg below horizontal. Lift and dump height reaches up to 104 in. Unit is suitable for situations where loads need to be dumped at different heights such as 48, 60, 72, 84, or 96 in. It is available in capacities of 1000, 2000, 4000, and 6000 lb with...

Read More »

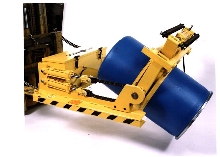

Drum Dumper handles more than a ton.

Forklift-mounted ADT-25 attachment runs on its own battery power and hydraulic system. It dumps and pours up to 2,500 lb steel, fiber and plastic drums, and has adapter for handling smaller, 12 in. drums. It has variable clamping pressure, adjustable speed control, battery and charger, 25 ft pendant switch cord, 180 deg pouring rotation, and rubber-faced clamp pads for fiber and plastic drums.

Read More »

Everything You Need to Know About Cold Chain/Temperature Controlled Packaging

This ebook provides an overview of everything you need to know about cold chain and temperature-controlled packaging.

Read More »

Drum Dumper rotates 180 degrees.

Control Link(TM) Rotation System provides controlled 180 deg rotation for maximum product discharge. Unit discharges drums of iron powder in hopper at 42 in. above grade. Lift and Seal System(TM) hydraulically seals drum to stainless-steel pour cone for dust-tight operation. Intrinsically-safe unit is suitable for use in hazardous environments.

Read More »

Bin Tilter reduces operator fatigue.

Stationary Bin Tilter enables operator to lift and tilt bin so that gravity feeding of parts occurs at ergonomically-correct height for worker. Toe clearance allows operator to stand tight against unit. Tilter is available in 2,000 and 4,000 lb capacities with self-contained, 110 V, 1-1/2 hp power pack. Hydraulic velocity fuse, chrome pins with maintenance-free bearings, push-button control, and...

Read More »

Von Ruden's Driven Tools Are Built to Last

Von Ruden's driven tools are designed to each specific machine in order to maximize performance. All of our tools are performance tested and made in the USA per ISO 9001:2015 standards. Check out our video to learn more.

Read More »