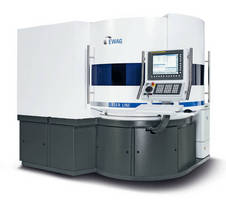

Radius Internal Cylindrical Grinders handle large workpieces.

WithÃ- workhead on simultaneously swiveling B-axis, STUDER S121, S131, and S141 offer thermal stability, mechanical rigidity, and interpolation from -60Ã-

Read More »

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

Normac's MX17 Seven Axis CNC Universal Tap Thread Grinding Machine

The MX17 is a completely new 7 axis Universal Thread Grinding Machine With CNC wheel dressing capabilities specifically designed for the manufacture of ultra precision taps and threaded components. Features Heavy duty cast polymer base to dampen vibration. Hydrostatic slide ways on all axis for the highest level of stiffness. Direct drive grinding wheel spindle with an automatic wheel balancer...

Read More »

Cylindrical Grinding Machines suit high-speed OD processing.

GRINDORÃ-® speed universal cylindrical grinding machines are designed for machining shaft-like parts or blanks for cutting tools. Systems use up to two grinding spindles with maximum grinding lengths of 500 mm. Machines allow circumferential speed of up to 140 m/sec when CBN or diamond abrasives are used.

Read More »

Peristaltic Pump Vs. i-FILL® Technology

Intellitech's advanced i-FILL® pumps are used by companies working in some of the world's most demanding sectors, delivering innovative, highly accurate and repeatable results, ensuring ultimate reliability and ease of use for all of our clients.

Read More »

Urea Prill Grinder delivers uniform particle size.

Urea Prill Gran-U-Lizer(TM) provides 90-95% yields for common urea or NPK prill grind sizes. Dust-tight system is infinitely adjustable and offers capacities from 2-20 Mtons/hr. Constructed of noncorrosive materials and high hardness rolls, it utilizes continuous roller-style method to maximize yield and minimize waste and energy usage. Grinder is suited for use in fertilizer process facilities.

Read More »

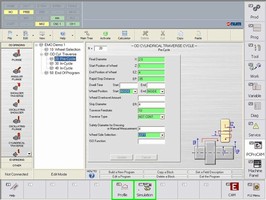

NUM's Solutions for Grinding Have User-Friendly Graphical and Conversational Programming

Exhibiting at IMTS 2006 in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 11, 2006 NUM offers a family of cost-effective control systems well suited to address all aspects of cylindrical and surface grinding. Configured with a state-of-the-art CNC, motors/drives, and very user-friendly software, these off the shelf solutions can be used in new machines or to retrofit existing machines....

Read More »

New HG 72 Universal Cylindrical Grinder

Modular concept grinding machine ideally suitable for medium to large components and medium volume production applications. Danobat Machine Tool Co. Inc, displays at IMTS 2006 edition the latest universality concept in medium - heavy duty grinding machines. Several machine configurations are available in order to satisfy market needs. Customers worldwide, OEM and subcontractors, have already...

Read More »

Kellenberger Grinder with New GRINDplusIT Control to Be on Display at IMTS '06

ELMIRA, NEW YORK: Kellenberger, a Hardinge company, now offers on their Kel-Varia cylindrical grinding machine the all-new and highly-advanced Heidenhain GRINDplusIT control and a central chiller system for the hydrostatics, electrical cabinet, spindle and motors to ensure unprecedented thermal stability. This new addition to Kellenberger's expanding line of high precision grinding machines will...

Read More »

Cylindrical Grinder turns/grinds shafts in single clamping.

Featuring Studer GranitanÃ-® S103 mineral inclined-bed machine base and integrated chip conveyor, Kairos S is designed for hard turning and grinding of rotational hard/fine applications for shaft and chucked workpieces. Modular design facilitates setup and changeover, while Fanuc 310i-A digital control offers step-by-step programming. Depending upon application, parts up to 1,000 mm can be...

Read More »

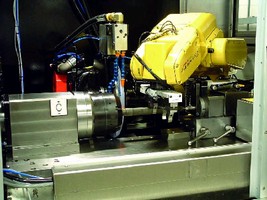

Thread Grinder features robot load/unload system.

Equipped with linear motors and ways, Model GS:TE-LM features 180Ã-

Read More »

Does Your Parking Lot Make a Good First Impression?

To enhance its appearance by removing oil stains, Terminator-HSD uses micro bacteria to remove the stain without harsh chemicals, acids, or detergents. Check out the video to learn more.

Read More »