Calender Roll Grinder grinds in-place.

Portable Roll Grinder mounts directly onto framework of calender equipment to let users grind rolls in their own bearings without hand or block grinding. Eliminating need to remove rolls, self-reversing, traversing grinder can redress calender rolls in-place up to 240 in. long. Grinder can achieve tolerances to 0.0005 in. on diameter, concentricity, and straightness, with finishes as fine as 12...

Read More »

Thread Grinder employs linear motors on linear ways.

Full helix thread grinder, model GS:TE-LM, allows operators to grind threads, splines, key slots, rings, and other forms on one machine in one setup. It also enables users to optimize dress and grind process by monitoring acoustical emissions. Machine automatically corrects wheel forms for helical path interference or generates forms using standard plated wheels. Product incorporates tenth-micron...

Read More »

ID Grinder handles mid-sized parts.

Suited for high-speed grinding, Opus features cast iron bed that resists torsional and bending forces. X-axis and Z-axis slides are independent, each mounted directly to machine bed. Digital servomotors, direct-coupled to precision ballscrews, provide positioning. Grinder machines product bore sizes from 0.40 to 7 in. dia and lengths to 3 in. X-axis travel is 2 in. and Z-axis travel is 10 in....

Read More »

Things to Consider Before Designing Custom Packaging

This e-Book provides pre-design process considerations for custom corrugated packaging.

Read More »

Grinding Machine Cell offers parallel machining alternative.

Juflex enables independent or synchronized machining, with 2 carriages in 2 grinding cycles. It features 2 machine bases, 2 hoods, and 1 control system, with grinding envelope in each module of 32 x 12 in. Workpieces are transported in cell by internal loading/unloading gantry. Input and monitoring is accomplished via EJ-OP operator panel. Juflex is suited for automotive transmission shafts and...

Read More »

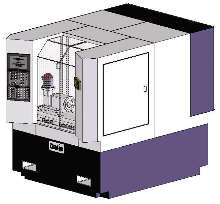

Cylindrical Grinding Machine has full enclosure.

With grinding envelope of 32 x 12 in., EJ30 employs rounded-accent enclosure that completely covers machining area. Product uses Fanuc system equipped with dedicated graphics-based software for pendulum, plunge-cut, and shoulder grinding. It also offers manual or automatic dressing programs with grinding wheel and diamond compensation. Software capabilities include simultaneous axis...

Read More »

Cylindrical Grinder performs internal and external grinding.

Model S33 utilizes digital, direct-drive, 3-phase servo motors with 40 mm dia ballscrews to power X- and Z-axes. Grinding spindle is powered by 7.5 kW motor. Universal turret wheelhead swivels manually or automatically, permitting external, internal, and face grinding of workpieces in single setup. Peripheral speed is up to 45 m/sec with infinitely adjustable speed control to 3200 rpm. Precision...

Read More »

Cylindrical Grinder tackles short runs and mixed lots.

Model S151cnc features modular design and digital control and drive systems. Swing diameter is 350 mm, between-centers grinding length is 200 mm, and chuck capacity is 150 kg. Turret head arrangement presents 2 grinding spindles for rough and finish grinding in same set-up. Spindle configuration is ID/ID or combination ID/OD for universal applications. Grinder features max spindle diameter of 170...

Read More »

CNC Machine provides centerless grinding of small parts.

Kronos S permits straight plunge grinding and 15Ã-

Read More »

Grinder uses GMP roller grinding technology.

Model IMD69 GMP Gran-U-Lizer(TM), pharmaceutical grade roller style grinder, incorporates three-stage progressive roller reduction design. It offers features such as full wash-down capability, controlled grinding environment (N2, Ar), water-cooling, and PLC controls. It is suited for GMP applications requiring narrow particle distribution with fines reduction of up to 75%.

Read More »

High or Low Volume Custom Crates and Boxes Available from Reid Packaging

Reid provides mil-spec crates and corrugated boxes in custom dimensions from single to triple wall and will even package them on-site. Check out the video to learn more.

Read More »