New CAD/CAM Nesting Software Easy to Learn and Use!

SigmaNEST Companion is easy to learn and use! (ST. MICHAEL, Minn. - November 24, 2008) - Jet Edge is now offering the easy-to-learn and use SigmaNEST Companion(TM)CAD/CAM nesting software on its precision waterjet cutting systems. Developed by SigmaTEK Systems, LLC, of Cincinnati, SigmaNEST Companion uses a wizard-based approach to allow waterjet operators with little or no CAD/CAM experience to...

Read More »Electronic Thermocutter weighs 11--½ oz.

With transformer replaced by high-tech electronics, AZTC-20 electronic thermocutter cuts synthetic fabrics, plastic tubes, fiber optics, foam and similar materials that tend to crimp, serrate or unravel when cold cutters are used. Temperature in unit is controlled from zero to 1050Ã-ºF, while electrical current control switch allows selection of large blades. Cutting foot accessory lifts...

Read More »

Waterjet Cutting Machine offers simplified overhead loading.

Featuring 21 x 13 ft work envelope, Jet Edge large-format Mid Rail Gantry Waterjet System includes exposed tank that accommodates overhead loading. Ball-screw driven system features abrasive jet cutting head and heavy-wall tubular steel construction that eliminates vibration. It utilizes industrial PC controller, with 3 axes fully programmable, direct-couple AC brushless digital servo motors, and...

Read More »

Fiber Laser Cutting Machine offers cutting-on-the-fly.

Equipped with fiber laser, direct drive motion control platform, and single pallet shuttle table, Titan Series utilizes TurboPiercing(TM) technology, which completes accurate hole, eliminating unnecessary craters in material. With Cutting-on-the-Fly feature, laser beam is turned on and off as needed and is accurately positioned via computer-aided alignments. Materials are fixed in place directly...

Read More »

The Importance of Branded Products For Your Business

This ebook discusses the importance and benefits of having branded products for your business.

Read More »Sandvik Coromant to Release Aerospace Engine Solutions Package

Fair Lawn, New Jersey, January 11, 2009 - Sandvik Coromant today announced its plan to release an Aerospace Engine Solutions Package in March 2009. The package will contain 5 standard products tailored to support the aerospace engine industry: o GC1115 - a new PVD coated grade for high temperature alloys offers improved toughness and excellent wear resistance o CoroCut angled inserts - the most...

Read More »Multipurpose Machine combines vinyl cutting and plotting.

Working with 15 or 24 in. wide rolls of 3.0 mil-thick vinyl, DuraCut II uses 400 grams of force to cut graphics/text at rates to 23.6 ips. Knife holder can be switched for felt tip pen for plotting and drawing. Signs are designed on PC via included software packages and printed on DuraCut II, which connects to PC through parallel, USB, or serial port. Features include digitally controlled servo...

Read More »

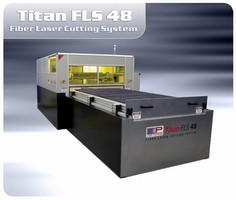

Fiber Laser Cutting System handles large scale jobs.

Based on 2,000-5,000 W upgradeable Fiber Laser, Titan FLS 48 comes equipped with single pallet shuttle table, Class I safety enclosure, and direct drive motion control platform. It has small heat affected zone and requires no optical system alignment, laser service, or laser replacement parts. In addition to cutting intricate designs and highly reflective metals such as aluminum, system is...

Read More »

Waterjet Cutter is optimized for handling large sheets.

Suited for steel service centers, Byjet L series features modular base frame that can be expanded in 6.5 ft increments and cutting areas from 6.5 x 10 ft (Byjet L 2030) to 52.5 x 10 ft (Byjet L 16030). All models include 2 High Precision Technology abrasive waterjet cutting heads with automatic head spacing, height sensing, and collision protection. Optional third and fourth cutting heads are...

Read More »

Cable/Wire Strippers .

Including Models K90-10/2, K90-12/2, and K90-14/2, Bent-Nose NM Romex-® Strippers feature tool steel black oxide finish, precision ground stripping holes, shear type cutting blades, and Klein-Kurve-® handles. Units eliminate need to angle tool, wire, or hand, enabling precise removal of outer jacket of non-metallic cable. They strip, cut, and loop 10, 12, or 14 AWG solid wire, and cleanly shear...

Read More »Laminator/Die Cut System helps eliminate waste.

Smart Laminator-Die Cut System synchronizes roll lamination and die cutting operations to eliminate causes of stock and laminate production waste. With smart sensors, system can detect sheet misfeeds, sources of improper laminating, or film splices, and automatically stops system so that corrective measures can be taken. Smart start and stop lamination controls also detect missing sheets and film...

Read More »

Optimize Your Storage or Distribution Facility with Steel King Rack Solutions

Steel King racks are designed to meet seismic requirements in the most demanding conditions. Our durable storage products help your company save on maintenance costs. Check out our product video or download our Rack Planning eBook to learn more.

Read More »