Watson Grinding & Manufacturing Turns to Romi for Turning Valve Components

Watson Grinding & Manufacturing is riding the oil drilling boom for all its worth down in Houston. This 47-year old company has built its reputation on offering complete turnkey manufacturing of critical oilfield components such as valves, pumps and compressor parts. The company has developed a variety of thermally-applied coating processes to solve erosion and corrosion problems facing today's...

Read More »GE Fanuc Automation Expands Capabilities of CNC Learning Control Function Greatly Improving Productivity for High Volume Machines

Next Generation of Learning Control Provides The Ability To Achieve High Speed and High Precision For Any Machining Application CHARLOTTESVILLE, VA, NOVEMBER 29, 2006 GE Fanuc Automation, a unit of GE Industrial, has announced that it has expanded the capabilities of its learning control function for parts cutting and rigid tapping providing the ability to apply the high speed and high precision...

Read More »

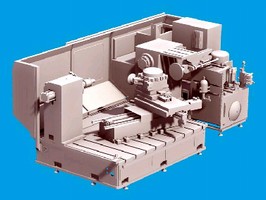

New ROMI E280 Offers Even Greater Multitasking Flexibility

ERLANGER, KY - Romi Machine Tools, Ltd, an industry leader in chip-making technology, has built a reputation on providing customer-driven solutions to a broad array of precision machined part challenges. The New Generation E Series of turning centers offers turning, boring, milling and tapping - all in one setup. It can be configured with one or two spindles with full C axis, live tools and a...

Read More »

CNC Bandsawing System minimizes set-up process.

Completely automating bandsawing processes, MBDÃ-® Model 4340 offers infinitely adjustable material clamp and max capacity of 60 x 20 x 14. Servo controlled feed table guides bandsaw blade along cutting path and through material. Machine eliminates need for templates and marking, automatically sawing block and panel materials. Automated process optimizes raw material yield, productivity, part...

Read More »

Application Selection Guide: Choosing the Right Air Compressor

Choosing the right air compressor for your application is essential, but it can feel overwhelming. To learn more about how to make the right choice, read our eBook.

Read More »GE Fanuc Automation Features Innovative Industry-Leading CNC/Servo Technology at IMTS 2006

Impressive Demonstrations of New CNC and Servo Products Highlight Changing The Game Theme Enabling Competitive Advantage for Manufacturers CHARLOTTESVILLE, Va. September 6, 2006 - GE Fanuc Automation, a unit of GE Industrial and the leading supplier of computer numerical controls (CNC) and related products, will be showcasing hardware, software and machine tool productivity solutions at this...

Read More »Dorian Tool International Introduces the Perfetta(TM) Live Center

The evolution never ends Dorian Tool International introduces the Perfetta(TM) Live Center. These live centers, which have already been recognized throughout the rest of the industrial world as the most precise live centers ever built, are now available to the American machine tool industry. Designed for turning on a CNC lathe or for use on a CNC grinding machine, the Perfetta(TM) live center has...

Read More »Maintenance Technologies Exhibits Adaptive Control & Monitoring Technology For CNC Machine Tools In Booth A-8218 at IMTS 2006

Chicago, IL, September 6, 2006 - Maintenance Technologies demonstrates their Adaptive Control & Monitoring (ACM) technology for CNC machine tools in Booth A-8218 at IMTS 2006. Maintenance Technologies is the North American distributor of OMATIVE System's ACM solution which helps manufacturers cut cycle times, reduce downtime, and minimize part cost by reacting to actual metalcutting conditions in...

Read More »

NUM's CNC System Makes Programming Spin Forming a Breeze

Exhibiting at IMTS in Chicago, Sept. 6 to 13, Booth D-3232 Chicago, September 12, 2006 NUM's Axium Power CNC system combines a compact CNC with powerful on-board programming tools for spin-forming processes. The embedded spinning functionality, together with guided pre-form and spin-cycle setup routines, is combined with a graphical and user-friendly interface, known as the HMI, to provide a...

Read More »

CNC Spin Machine offers swing distance of 72 in.

Equipped with teach-in joystick and SpinCAD(TM) CNC programming software, Model SP-7260 features 60 hp spindle with speed range of 3-300 rpm/12-1,200 rpm and 4-station automatic turret designed to handle multiple spinning and machining operations. Material capacity is .375 in. mild steel, .250 in. stainless steel, and .500 in. aluminum. With SpinCAD software, programs can be developed, saved, and...

Read More »CNC Controller suits thermal metal cutting machines.

Featuring 15 in. touch screen with IntelliTouch Surface Wave technology, 6-axis Voyager III is based on 2.4 GHz Intel processor using Hypertherm Automation CNC Software v6.0. Machine interface converts SERCOS fiber optic communication to analog interface for motion commands and I/O. It offers choice of enclosure-mounted analog interface, SERCOS communication ring, or remote-mounted...

Read More »

Acoustic and Thermal Solutions for Original Equipment Manufacturers

Technicon's products solve the most complex noise pollution and thermal problems and improve product marketability. Check out the video to learn more.

Read More »