Affordable Productivity from NCMT with Launch of Entry-Level Okuma Machines

New turning machine to make UK debut; machining centres also to be announced NCMT will launch at MACH 2012 a new range of early-entry machine tools from Okuma, a Japanese manufacturer better known for its high-end machining centres and lathes. Called GENOS, the programme comprises two machining centres and fourteen CNC turning centres, one of which, a twin-spindle model, will be under power at...

Read More »

Patented Platform Centering Device

Advance Lifts, Inc. of St. Charles, Illinois, is pleased to announce that our NEW Patented Platform Centering Device. Off centered loading of scissors lifts is a major contributor of excess wear on rollers, bearings, platforms and scissors legs, causing premature failure of any or all of these components. The wear occurs because the off center loading forces the platform to shift sideways toward...

Read More »

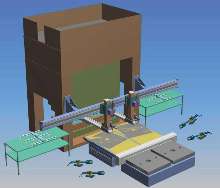

Centering Station relies on programmable motion paths.

Vision-based centering station uses cameras and control system to compare actual position of blanks to desired in-die position. It determines appropriate motion path required by feeders to properly align blanks prior to entering press. Station consists of 2 telescoping shuttle systems with rotate units and automatic end-effector disconnect plates, 2 cameras and lighting systems, press-mount...

Read More »

Industrywide Applications for Deep Drawn Metal Stamping

Deep-drawn metal stamping applies a significant punching force to radically draw metal sheets into a die cavity. Finished components produced by this process tend to have a depth that exceeds their diameter, which is why manufacturers refer to it as "deep-drawn" metal stamping.

Read More »

End Facing and Centering Machines work both ends simultaneously.

Model MC 650 has 2 horizontally opposed #50, 20 hp taper spindles, each with 3-axis CNC plus 20-position automatic tool changer. Work capacity is 8 in. dia. x 59 in. long, suitable for machining solid shafts, with or without flanges, bars, and tubular-type parts. Model CM 132/IS040/TC12 has 2 horizontally opposed #40 taper spindles, each with 2-axis CNC and 12-position tool changer, for work...

Read More »

DoorKing Releases Advanced Long Range Card Reader System with Frequency Hopping Technology

The DoorKing DKS AVI system is at the cutting edge of automotive security technology and represents a leap forward in engineering innovation. When it comes to long-range passive card readers, we lead the industry and set the standard for quality and performance. To find out why the DoorKing DKS AVI system is taking the automotive security industry by storm, see our video.

Read More »