New Dragon 15 Robotic Brazing System is Capable of Brazing Multiple Joints

Features integrated induction coil mounted onto the robotic arm. Can work with 15 KW induction system and a wire feeder. Capable of programming wire feeder to start when the heating temperature had been reached.

Read More »

MetalMaster-® Continues to Support Aerospace Industry

CHERRY VALLEY, IL – A company in southern Singapore, specializing in the repair and refurbishment of commercial jet engine turbine airfoils, recently acquired an Ipsen 2 bar MetalMaster® vacuum furnace. Customers often look to the MetalMaster line due to its sustained relevance and reputation in the industry, says Craig Moller, Ipsen's Chief Engineer, It works well and it will continue to work...

Read More »Inductoheat, Inc.: 21 Systems Shipped and Order Is Complete

Madison Heights, MI - Inductoheat, Inc., the world's leading induction heating equipment manufacturer, shipped the last StatiScanÃ-® IV system of a 21 unit order. These customized systems were manufactured for a world leader in the mining and oil sands exploration and are being used for induction hardening and tempering drill rods and hardening pipe-end threads. For more information about...

Read More »Lynch Metals Introduces Three-Layer Brazing Sheet

Introducing Lynch Metals new Multiclad product which is a three-layer product that offers several advantages over brazing sheet products consisting of only two layers. By adding an interlayer between the cladding and the core layers, multiclad has reduced the silicon penetration that occurs during brazing. The 3003 interlayer inhibits silicon from the cladding to diffuse into the core material....

Read More »

Guide to Replacement Fuel Tanks

What to consider when your fuel tank needs to be replaced.

Read More »

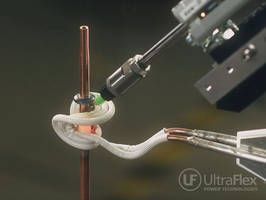

Induction Heating System automates industrial brazing.

Designed for open-air brazing and soldering in lean manufacturing environment, AB-1 occupies 5 x 6 ft footprint and includes 4- or 6-position indexing table. It can be configured with up to 3 brazing stations as well as robotic part loading and unloading. Front panel start/stop push buttons place system in PLC-controlled auto run mode, with full manual control available for process development....

Read More »

Brazing Machine features automatic operation.

CB Lite II(TM), suited for small production runs and job shops, is equipped with repeatable PLC setup to control heat, air, and water cycle times. Able to be re-tooled and re-torched for quick application changeover, moveable machine is designed for use with rings or preforms. Unit will oscillate torches across joint or rotate part for uniform heating. Operator loads part and pushes button. All...

Read More »

Manifold Brazing Machine features automatic operation.

LB(TM) Linear Brazer automatically brazes manifolds and headers producing parts with consistent quality. It automatically senses size and position of each tube, locates joint to be brazed, and oscillates torches around joint for uniform heating. Machine optically senses correct brazing temperature and feeds brazing alloy to joint. Unit can have nitrogen purge and introduce Gasflux(TM) into flames...

Read More »

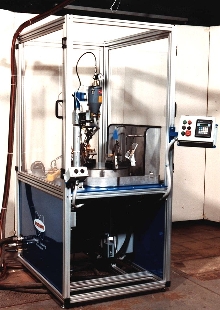

Brazing/Soldering Machine is designed for small assemblies.

Rotary Index 100 is 36 in. wide by 48 in. deep and operates at rates between 100 and 200 parts per hour, depending on assembly mass and configuration. Brass, copper, steel, stainless, and aluminum can be joined on machine. Unit is equipped with clear, acrylic guarding on 3 sides. It requires 120 VAC, natural gas or propane, 80 psi air, water and drain.

Read More »

Complete Water Solutions Offers Wide Range of Water Treatment Equipment

Complete Water Solutions provides full installation tailored to your water treatment needs. Check out the video to learn more.

Read More »