CPS Corp.

Dunkirk, NY 14048

Share:

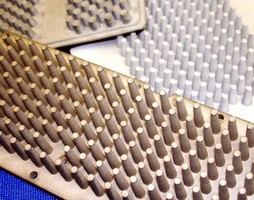

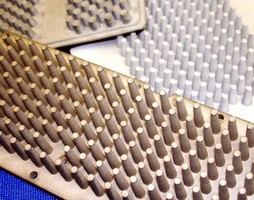

Metal Matrix Composite enhances thermal performance.

AlSiC features high stiffness to low density ratio, making it structurally suited for large parts with thin cross sections while enabling incorporation of thermal management features such as pin fins. Pins are cast during AlSiC pressure infiltration process and are targeted for microprocessor lids or liquid cooled IGBT base plates. Tailored, isotropic coefficient of thermal expansion provides...

Read More »

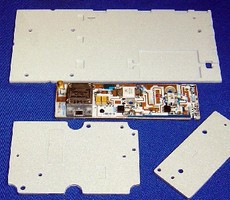

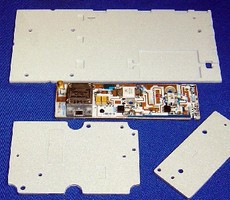

Metal-Matrix Composite provides thermal management.

Suited for IGBT base plates, Aluminum Silicon Carbide Composite is RoHS-compliant and features high thermal conductivity, preventing bowing and flexing of packaging and substrate material. Isotropic coefficient of thermal expansion can be adjusted for specific applications by modifying Al-metal/SiC-particulate ratio to match CTE of die or substrate. Base plates can be used in high-power traction,...

Read More »Metal Matrix Composite has adjustable CTE value.

AlSiC (Aluminum Silicon Carbide) enables tailored coefficient of thermal expansion (CTE), offering compatibility with various electronic devices and assemblies; isotropic CTE value is adjusted by modifying Al-metal/SiC-particulate ratio. Thermal conductivity of material prevents bowing and flexing of packaging and substrate material. Product is suited for housing, interconnection, and thermal...

Read More »CPS Technologies Doubles Manufacturing Space

CPS Technologies, the worldwide leader in the design and production of metal matrix composites, announces that the company has entered into a 10-year lease to double manufacturing space at its current location. CPS has been leasing 18,000 square feet at 111 South Worcester Street in Chartley, MA for the past 12 years. The newly signed lease provides the company with 38,000 square feet at the same...

Read More »

Metal Matrix Composite enhances thermal performance.

AlSiC features high stiffness to low density ratio, making it structurally suited for large parts with thin cross sections while enabling incorporation of thermal management features such as pin fins. Pins are cast during AlSiC pressure infiltration process and are targeted for microprocessor lids or liquid cooled IGBT base plates. Tailored, isotropic coefficient of thermal expansion provides...

Read More »

Metal-Matrix Composite provides thermal management.

Suited for IGBT base plates, Aluminum Silicon Carbide Composite is RoHS-compliant and features high thermal conductivity, preventing bowing and flexing of packaging and substrate material. Isotropic coefficient of thermal expansion can be adjusted for specific applications by modifying Al-metal/SiC-particulate ratio to match CTE of die or substrate. Base plates can be used in high-power traction,...

Read More »CPS Awarded Patent for AlSiC Composite with Integrated Heat Exchanger

Advanced thermal management for active cooling application CPS Corporation, the worldwide leader in the design and production of metal matrix composites, offers AlSiC (Aluminum Silicon Carbide), a metal matrix composite that provides high-performance heat spreaders, packages, and substrates for the flip-chip IC packaging, power control, and optoelectronic markets. CPS has recently been awarded a...

Read More »Metal Matrix Composite has adjustable CTE value.

AlSiC (Aluminum Silicon Carbide) enables tailored coefficient of thermal expansion (CTE), offering compatibility with various electronic devices and assemblies; isotropic CTE value is adjusted by modifying Al-metal/SiC-particulate ratio. Thermal conductivity of material prevents bowing and flexing of packaging and substrate material. Product is suited for housing, interconnection, and thermal...

Read More »