Metal-Matrix Composite provides thermal management.

Share:

Press Release Summary:

Suited for IGBT base plates, Aluminum Silicon Carbide Composite is RoHS-compliant and features high thermal conductivity, preventing bowing and flexing of packaging and substrate material. Isotropic coefficient of thermal expansion can be adjusted for specific applications by modifying Al-metal/SiC-particulate ratio to match CTE of die or substrate. Base plates can be used in high-power traction, power control, and fly-by-wire applications.

Original Press Release:

CPS Introduces Revolutionary Metal-Matrix Composite

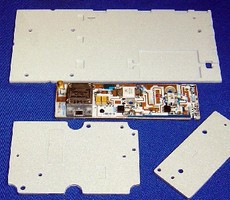

CPS Corporation, the worldwide leader in the design and production of metal matrix composites, offers AlSiC (Aluminum Silicon Carbide), a metal matrix composite ideally suited as a thermal management material for insulated gate bipolar transistor (IGBT) base plates. These plates can be used in high-power traction, power control, and fly-by-wire applications, which require thermal performance reliability. The IGBT baseplates are light weight and offer high strength. The thermal performance reliability AlSiC composites offer is ideal for the production of high reliability military electronics. AlSiC has been tested and meets the requirements of the Restriction of Hazardous Substances Directive (RoHs compliant) of the European Parliament.

AlSiC's tailored, isotropic coefficient of thermal expansion (CTE) can be adjusted for specific applications by modifying the Al-metal/SiC-particulate ratio to match the CTE of the die or substrate. AlSiC's CTE matching eliminates the need for thermal interface stacking and ensures IGBT base plate compatibility with ceramic substrate attachments for high-power applications.

Coupled with its superior CTE matching, AlSiC's high thermal conductivity offers superior reliability and longevity by preventing the bowing and flexing of packaging and substrate material. Traditional packaging materials with lower thermal dissipation can cause delamination, leading to air gaps and failure. Unlike base plates made with copper and aluminum, AlSiC base plates survive thousands of cycles without delamination of the substrate from the baseplate.

The CPS AlSiC near net-shape fabrication process both produces the composite material and fabricates the product geometry, allowing for the design of IGBT base plates with a dome profile. This geometry improves thermal interface contact with cold plates and coolers, adding to AlSiC's advanced thermal management qualities.

About CPS Corporation

CPS Corporation is the worldwide leader in the design and high-volume production of metal matrix composites. With over 30 years combined experience, CPS engineers and scientists use a net-shape fabrication process, including patented QuickSet(TM) injection molding and QuickCast(TM) infiltration. AlSiC components are utilized in applications in the wireless communications infrastructure, high-performance microprocessor, motor controller, and other microelectronic markets. CPS' customers include TI, Motorola, HP, Agilent and Amkor. For more information on CPS' AlSiC components, contact CPS at 1 (508) 222-0614 x42; e-mail marko@alsic.com, or visit www.alsic.com.