Metal Matrix Composite enhances thermal performance.

Share:

Press Release Summary:

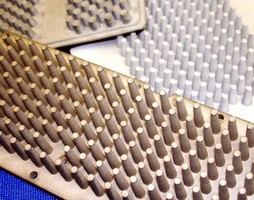

AlSiC features high stiffness to low density ratio, making it structurally suited for large parts with thin cross sections while enabling incorporation of thermal management features such as pin fins. Pins are cast during AlSiC pressure infiltration process and are targeted for microprocessor lids or liquid cooled IGBT base plates. Tailored, isotropic coefficient of thermal expansion provides compatibility with electronic assemblies, devices, and dielectric substrates.

Original Press Release:

CPS Introduces Advanced Cooling Capabilities

Easily integrated pin fins enhance thermal performance

CPS Corporation, the worldwide leader in the design and production of metal matrix composites, offers AlSiC (Aluminum Silicon Carbide), a metal matrix composite that enables the cost-effective integration of pin fins for high power applications, such as traction, industrial drive and pulse power.

AlSiC's high stiffness to low density ratio is structurally ideal for larger parts with thin cross sections and enables the easy and effective incorporation of advanced thermal management features, such as pin fins. Pins are cast during the AlSiC pressure infiltration process and are suitable for microprocessor lids or liquid cooled IGBT base plates. By increasing the cooling surface area available for heat transfer, pin fins allow more efficient dissipation of heavy heat loads.

AlSiC's tailored, isotropic coefficient of thermal expansion (CTE) provides compatibility with electronic assemblies, devices and dielectric substrates to improve product reliability in the field. AlSiC lids and baseplates prevent the bowing and flexing of packaging and substrate, eliminating failures due to delamination or cracking. In addition, AlSiC exhibits a high thermal conductivity that provides high thermal dissipation.

AlSiC's unique casting process enables the cost-effective integration of pin fins and other advanced thermal management solutions, such as very high thermal conductivity inserts (>1000 W/mK) or cooling tubes. The CPS AlSiC near and net-shape fabrication process both produces the composite material and fabricates the product geometry, resulting in a cost-effective product.

About CPS Corporation

CPS Corporation is the worldwide leader in the design and high-volume production of metal matrix composites. With over 30 years combined experience, CPS engineers and scientists use a net-shape fabrication process, including patented QuickSet(TM) injection molding and QuickCast(TM) infiltration. AlSiC components are utilized in applications in the wireless communications infrastructure, high-performance microprocessor, motor controller, and other microelectronic markets. CPS' customers include TI, Motorola, HP, Agilent and Amkor. For more information on CPS' AlSiC components, contact CPS at 1 (508) 222-0614 x42; e-mail marko@alsic.com, or visit www.alsic.com.