United Grinding North America, Inc.

Miamisburg, OH 45342

Radius Internal Cylindrical Grinders handle large workpieces.

WithÃ- workhead on simultaneously swiveling B-axis, STUDER S121, S131, and S141 offer thermal stability, mechanical rigidity, and interpolation from -60Ã-

Read More »

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

UNITED GRINDING Schedules North American Tour for New STUDER S11

MIAMISBURG, Ohio – Beginning next month, UNITED GRINDING will make it possible for manufacturers to get in front of the latest precision cylindrical grinding technology without having to travel far. The company has plans to take its new compact, highly productive STUDER S11 for small workpiece production on a six-city tour across the United States as well as make the machine a focal point at...

Read More »

Grinding Machine suits small-scale and high-throughput jobs.

Combining ID and OD grinding to promote efficiency and output, Studer S33 incorporates control and wheelhead for grinding complex workpiece geometries in one clamping. StuderWIN graphical interface and 15 in. touchscreen for CNC control with integrated PC facilitate programming, and technology calculator is provided for definition of process parameters. Supporting full machining range, product...

Read More »

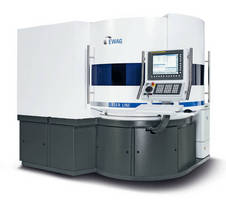

CNC Tool Grinder features linear motors.

Helitronic Vision CNC tool grinder grinds carbide or HSS tools ranging from 1/8-12.6 in. dia. Machine features 2 rotary and 3 linear axes with direct drive linear motors that move up to 2,000 ipm, and dampening is provided by mineral casting for machine base and gantry. Tool Studio software offers ability to setup while machine grinds, and machine can be equipped with both automatic tool loader...

Read More »

Profile Grinder performs ultra-precise work.

Surface and profile grinding machine, Jung J 630, is suited for applications where it is necessary to produce micron-precise contours and profiles or ultra-fine finishes. PA 37 dressing system allows continuous profile dressing of grinding wheel, simultaneous with grinding process, while double V guide construction provides rigidity and stability. Grindable workpiece surface including wheel width...

Read More »

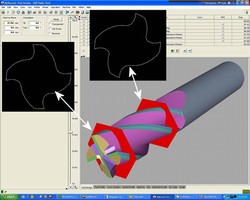

Tool Grinding Software promotes operational flexibility.

Helitronic Tool Studio facilitates design and manufacture of complex or unique cutting tools. With this program, user can change any feature of interactive 3D graphic to model tool. When model meets user's approval, it can be sent straight to machine because grinding program is already written in background. All programming can be accomplished from office PC instead of grinding machine, and user...

Read More »

Small-Tool Grinder achieves accuracies within 1.5 microns.

Offering automatic in-process regeneration (IPR) of grinding wheel, EWAG EWAMATIC line grinds and erodes round tools and inserts in PCD and carbide. Direct-drive C-axis workhead (PEK axis) lends to overall grinding precision and productivity. Using torque motor results in axis speeds to 1,000 rpm. While max wheel size is 11.8 in., max clamping power is 7,000 N. Automatic hydraulic compensation...

Read More »

Machine measures micro tools down to 0.004 in. dia.

Featuring 4 fixed CCD cameras, 4 CNC axes, and granite base to dampen vibrations, HELICHECK PLUS automatically measures virtually all geometries on tools down to 0.004 in. in diameter with repeatability of Ã-

Read More »

Cylindrical Grinder turns/grinds shafts in single clamping.

Featuring Studer GranitanÃ-® S103 mineral inclined-bed machine base and integrated chip conveyor, Kairos S is designed for hard turning and grinding of rotational hard/fine applications for shaft and chucked workpieces. Modular design facilitates setup and changeover, while Fanuc 310i-A digital control offers step-by-step programming. Depending upon application, parts up to 1,000 mm can be...

Read More »UNITED GRINDING North America Partners with Dynamic Machine

MIAMISBURG, Ohio, March 10, 2020 – UNITED GRINDING North America Inc. announced it has entered into a partnership with Dynamic Machine of Detroit, a Troy, Michigan-based CNC equipment dealership. For those UNITED GRINDING North America customers in the Michigan territory, the partnership will further strengthen grinding machine sales, service and application support. With over 200 years of...

Read More »UNITED GRINDING NORTH AMERICA Names New President/CEO

MIAMISBURG, Ohio, January 9, 2020 – Markus Stolmar has been elected as the new president and chief executive officer by the board of directors for UNITED GRINDING North America. The appointment is effective immediately. Stolmar was selected for this position after serving nearly 20 years in various leadership capacities within the company, starting as the product manager for the optical...

Read More »UNITED GRINDING Launches Motion Blog

One-stop source for grinding, eroding, measuring and laser ablation knowledge and expertise MIAMISBURG, Ohio, September 9, 2019 – Manufacturing is continuously changing, and manufacturers need to stay ahead of the curve to be successful. To ensure they do, UNITED GRINDING North America has launched a new blog called Motion to provide a convenient one-stop source for UNITED GRINDING North...

Read More »UNITED GRINDING North America Launches STUDER Stud-E Bucks Program

Miamisburg, Ohio, August 13, 2019 – Committed to helping manufacturers across the continent make the most of their budgets when upgrading cylindrical grinding equipment, UNITED GRINDING North America has announced a special program that expands access to the company’s comprehensive range of solutions. For every qualified purchase of one of the company’s in-stock STUDER machines,...

Read More »UNITED GRINDING North America Announces Key Promotions to Leadership Team

MIAMISBURG, Ohio, July 17, 2019 – As part of its continued efforts to provide customers with the highest level of service, UNITED GRINDING North America has announced several organizational changes and promotions. These changes, which include an expanded executive vice-presidential position and a planned transition of leadership for the Tool Division, will serve as a further investment in the...

Read More »UNITED GRINDING North America Wins Sales Growth Award at 20th Annual FANUC ASI Event

MIAMISBURG, Ohio, March 1, 2019 – UNITED GRINDING North America earned recognition for the outstanding growth of its sales of FANUC robotic systems at the 20th annual FANUC Authorized Systems Integrators (ASI) Meeting. The awards ceremony, which took place in Scottsdale, Arizona, on February 12, 2019, honored distributors and manufacturers alike who, like UNITED GRINDING North America’s...

Read More »United Grinding North America Wins Sales Growth Award at 20th Annual FANUC ASI Event

Miamisburg, Ohio, March 1, 2019 – United Grinding North America earned recognition for the outstanding growth of its sales of FANUC robotic systems at the 20th annual FANUC Authorized Systems Integrators (ASI) Meeting. The awards ceremony, which took place in Scottsdale, Arizona, on February 12, 2019, honored distributors and manufacturers alike who, like United Grinding North America’s...

Read More »UNITED GRINDING North America Names Ellison Technologies as New Distributor

MIAMISBURG, Ohio, February 4, 2019 – UNITED GRINDING North America welcomes nationwide solutions provider Ellison Technologies as a key distributor, serving as the exclusive representative of the company's grinding solutions in Texas and Louisiana. With more than 60 years' experience, Ellison Technologies offers an extensive full-time sales staff, large service and support network, engineering...

Read More »United Grinding Group Celebrates Flow Assembly Line Launch

MIAMISBURG, Ohio, April 11, 2018 – United Grinding Group AG held an event in its Kuřim, Czech Republic-based Walter Maschinenbau GmbH production facility to announce its new flow assembly line. Speakers included WALTER CEO Jürgen Schock and flow assembly line project manager Markus Schulze, both of whom welcomed guests and introduced the new innovation prior to pressing a symbolic start...

Read More »United Grinding Presents The Artistry of the Grinding Universe Event

MIAMISBURG, Ohio, March 8, 2018 - UNITED GRINDING North America, Inc. will host The Artistry of the Grinding Universe Event April 18–19 at its new 110,000-square-foot headquarters in Miamisburg, Ohio. The free two-day education event will give attendees an opportunity to explore the latest grinding technologies, automation and measurement systems that provide the turnkey solutions they require...

Read More »