Tool Grinding Software promotes operational flexibility.

Press Release Summary:

Helitronic Tool Studio facilitates design and manufacture of complex or unique cutting tools. With this program, user can change any feature of interactive 3D graphic to model tool. When model meets user's approval, it can be sent straight to machine because grinding program is already written in background. All programming can be accomplished from office PC instead of grinding machine, and user can add any number of grinding operations per tool as well as mix and match operations.

Original Press Release:

New Tool Grinding Software Combines Unlimited Flexibility with Ease of Use

"What you model is what you grind"

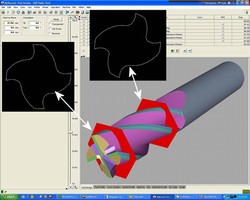

Walter Grinders' new Helitronic Tool Studio software makes it easy to design and manufacture complex or unique cutting tools. With Tool Studio, the user models the tool with an interactive 3D graphic-changing any feature. When he likes what he sees, he can send it straight to the machine because the grinding program has already been written in the background. To maximize productivity, the user can do all his programming an office PC instead of the grinding machine. Walter will grind custom cutting tools in over 1,800 variations at IMTS in the United Grinding booth, B-6700.

"What You Model Is What You Grind"

Every change appears instantly in a high-resolution 3D graphic and automatically rewrites the grinding program in the background.

Unlimited flexibility

The user can add any number of grinding operations per tool, mix and match operations, and change any individual feature to create geometries of any complexity. Everything-including simulation- is within one software program and everything is changeable: Variable helix...Variable rake...Variable core...Variable land width...Changing feed rates during an operation...Everything.

Click to edit anything from one screen-Saves time and aggravation

Simply clicking the 3D graphic allows the user to see anything relevant to that part of the tool: grinding parameters, operations, wheel data, a 2D cross section, a profile view, and a complete machine view. He doesn't have to hunt through separate windows and menus. Plus he can measure tool features from this central screen, correct any errors, try new design ideas, and check the results instantly-before grinding any real tools. Helitronic Tool Studio also lets him measure and optimize cycle times for individual operations and the complete grind. This also helps improve production planning and cost estimation.

Wizards offer easiest way to make standard tools

For standard tool families, Wizards shows only the relevant data, minimizing the data input required. The software then uses a database built on decades of WALTER tool grinding experience to complete the grinding program with astounding speed. At the same time, more proficient users can take a standard tool as the basis for more complex designs by adding new operations.

United Grinding in brief

United Grinding is the North American arm of Körber Schleifring and has two main offices. The factory in Fredericksburg handles EWAG and Walter tool grinders and measuring machines, while the Ohio facility supports Studer, Blohm, Jung, Mägerle, Schaudt, and Mikrosa cylindrical and profile grinders. The Körber Group as a whole has over 8,000 employees worldwide and over a billion dollars in sales. Visit United Grinding at www.grinding.com.