Hardinge Inc.

PO Box 1507

Elmira, NY 14902

New Bridgeport V-1320 Vertical Machining Center Comes with Dual Y-axis Ballscrews

Equipped with a 15 Mitsubishi M80 Color LCD touch screen with zoom in and out, scroll through screens, move pop-up windows and drag with a single finger options. Features Big Plus, 40 taper, 12,000-rpm Direct Drive spindle. Oversized 45 mm double nut ballscrews, fixed and pre-tensioned linear guideways supported by 6 trucks on the X and Z Axis.

Read More »

Hardinge Supplies a Precision Grip for Medical Component Manufacturing

Hardinge, well known in the industry for their SUPER-PRECISIONÃ-® products, provides gripping solutions for machining small diameter parts for medical component manufacturing. One category of products includes Swiss-type headstock collets, pickoff collets, carbide guide bushings, bar loader collets and custom manufactured solutions for Swiss turning. Their Swiss-type collets are finish ground...

Read More »

Medical Manufacturing Turns to Hardinge SUPER-PRECISION-® Gang-Tool Turning Center

Medical part manufacturing continues to be a rapidly growing market due to the large population of aging baby boomers who are looking for improved quality of life . Demand is high for high-precision components for neurological, orthopeadic, spinal/bone fixation, dental implants, drug infusion, catheter connectors, optical, maxillofacial, micro/minimally invasive, surgical instruments and other...

Read More »

Direct-Drive Rotary...Hardinge EASTEC booth #5045

Hardinge direct-drive rotary systems, manufactured in Elmira, New York, provide flexible, high-speed, SUPER-PRECISIONÃ-® rotary parts positioning. These rotary tables have zero backlash, permitting rapid bi-directional movement without the loss of time used to compensate for position over-travel which means more time in the cut. Direct-drive rotary units are ideal for parts that require...

Read More »

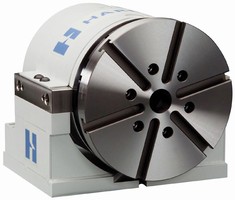

Rotary Table offers high-precision gripping options.

Equipped with collet-ready 16C spindle, 210 mm Model GD210LP accepts standard 16C collets, step chucks, Sure-GripÃ-® expanding collets, and custom collets with optional collet closer. Stiffness and rigidity are achieved with large diameter bearings and fail-safe clamp systems, allowing part weights up to 220 lb. With up to 233 lb-ft clamping torque, table handles off-center drilling,...

Read More »

Productivity Options for Multi-Spindle Automatics...

Should you consider using master collets and feed fingers instead of solid? Are you having trouble with slippage or marks on your workpiece? Can you really afford to purchase that ID pickoff attachment for your machine? You do have options. Hardinge has over a century of experience in designing and providing workholding solutions. We can help reduce setup and changeover times and help you grip...

Read More »

Hardinge Partners with Technitron for Rotary Table Interfacing and Installation

Hardinge (Elmira, New York) manufactures enhanced gear-driven rotary tables and indexers along with leading edge direct-drive rotary products. Hardinge rotary products are of a universal design for compatibility with any brand of machining center and can be run with a servo control box or as a 4th-axis interface. Hardinge is partnering with Technitron Inc. for their expertise in rotary...

Read More »

Lathe features electronic servo motor and threading computer.

With thread range of 4.0-250.0 TPI, Model HLV can machine up to 4 multiple-start threads. Brushless servo motor provides 44 lb-in. of continuous torque to 8-pitch threading lead screw, while 3.2 in. LCD provides visual threading information. Digital readout includes set zero mode for each axis, diameter/radius mode, inch/metric mode, and absolute/incremental mode. Offering infinitely variable...

Read More »

Hardinge HQC Quick-Change Collets

Hardinge Inc., Workholding Division August 10, 2006 Hardinge-® HQC-® Quick-Change Collets take the ups and downs out of bar work... Faster changeover than standard collets and more flexible than master collets and pads, the HQC-® Quick-Change Collet Systems by Hardinge offer long life, can accommodate bar stock variation and provide the opportunity for increased spindle speeds. The flexible...

Read More »

Direct-Drive Rotary System offers precise positioning.

Featuring 10 in. slotted face plate, DD200 high-speed gearless rotary unit employs direct-drive design that eliminates backlash and provides accurate bidirectional response with repeatability of Ã-

Read More »Hardinge to Bring Manufacturing Capacity Back to the United States

'Made in the USA' Manufacturing Shift to Support American Manufacturing, Create U.S. Manufacturing Jobs, Provide Shorter Lead Times and deliver Higher Performing Products required for the American Market ELMIRA, New York, Dec. 14, 2020 /PRNewswire/ -- Hardinge Inc., a leading international provider of advanced metal-cutting and material-cutting tool solutions and accessories, today announced...

Read More »

New Bridgeport V-1320 Vertical Machining Center Comes with Dual Y-axis Ballscrews

Equipped with a 15 Mitsubishi M80 Color LCD touch screen with zoom in and out, scroll through screens, move pop-up windows and drag with a single finger options. Features Big Plus, 40 taper, 12,000-rpm Direct Drive spindle. Oversized 45 mm double nut ballscrews, fixed and pre-tensioned linear guideways supported by 6 trucks on the X and Z Axis.

Read More »Hardinge to Acquire Voumard

ELMIRA, N.Y. –Ã- Hardinge Inc. (Nasdaq:HDNG), a leading international provider of advanced metal-cutting solutions and accessories, announced today that it has entered into an agreement to acquire the assets of the Voumard Internal Diameter (ID) Grinding Business from Peter Wolters GmbH in Rendsburg, Germany. Voumard, founded in Neuchatel, Switzerland nearly 70 years ago, has been a global...

Read More »Hardinge Inc. Sells Swiss Workholding Business

ELMIRA, N.Y. –Ã- Hardinge Inc. (Nasdaq:HDNG), a leading international provider of advanced metal-cutting solutions, announced today the sale of its Swiss Forkardt workholding operations for initial consideration of approximately $5.9 million, net of cash remaining with the business. After a comprehensive sales process, the successful bidder was a private group that was led by management of...

Read More »Hardinge Inc. Appoints Douglas J. Malone as Vice President and Chief Financial Officer and Edward J. Gaio as Vice President, Business Development

ELMIRA, N.Y. –Ã- Hardinge Inc. (Nasdaq:HDNG), a leading international provider of advanced metal-cutting solutions, announced that its Board of Directors at its meeting on December 10, 2013, appointed Douglas J. Malone as Vice President Chief Financial Officer and Edward J. Gaio as Vice President, Business Development. Mr. Malone and Mr. Gaio will both report to Richard L. Simons, Chairman,...

Read More »Usach Announces New Sales Manager

Usach Technologies, Inc., a wholly owned subsidiary of Hardinge Inc., announced today, effective June 24, 2013; Mr. Daniel Rey will assume the position of Sales Manager for Usach Technologies, Inc. Mr. Rey has over 25 years of professional experience in the machine tool industry with particular expertise in grinding machines and applications. He worked as a Regional Sales Manager for United...

Read More »

Hardinge Supplies a Precision Grip for Medical Component Manufacturing

Hardinge, well known in the industry for their SUPER-PRECISIONÃ-® products, provides gripping solutions for machining small diameter parts for medical component manufacturing. One category of products includes Swiss-type headstock collets, pickoff collets, carbide guide bushings, bar loader collets and custom manufactured solutions for Swiss turning. Their Swiss-type collets are finish ground...

Read More »

Medical Manufacturing Turns to Hardinge SUPER-PRECISION-® Gang-Tool Turning Center

Medical part manufacturing continues to be a rapidly growing market due to the large population of aging baby boomers who are looking for improved quality of life . Demand is high for high-precision components for neurological, orthopeadic, spinal/bone fixation, dental implants, drug infusion, catheter connectors, optical, maxillofacial, micro/minimally invasive, surgical instruments and other...

Read More »Custom Workholding Engineers on Hand at IMTS Booth S-8148

Hardinge Inc. (Elmira, NY) manufactures workholding products to grip parts to be turned, milled, ground, welded, assembled or positioned in the small-to-medium parts machining industry. Hardinge has completed over 200,000 custom workholding designs, while offering over 40,000 standard products. Their group of workholding engineers has over 300 years of combined experience in designing solutions...

Read More »One Team. 30 Hands. 300 Years of Engineering Experience

Hardinge Inc. (Elmira, New York) has a talented group of workholding engineers with over 300 years of combined engineering experience. These hands (and intelligent minds) are ready to improve accuracies, reduce setup times, reduce costs, add flexibility to a machine, develop new workholding concepts and solve gripping problems. There isn't a shop worldwide that can say they've never had a problem...

Read More »