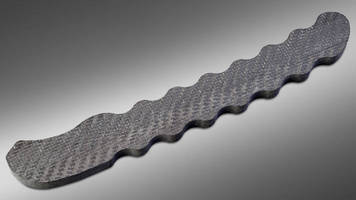

Nanocomposite delivers extreme fracture toughness.

Toughened with carbon nanotubes, ArovexÃ-® HT features Kentera™ technology, which acts as bridge between carbon nanomaterials and resin matrix. Kentera effectively disperses nanomaterials, allowing their mechanical property advantages to transfer loads from resin matrix to fibers, resulting in stronger products. Prepreg optimizes durability of carbon fiber products found in sporting goods,...

Read More »

Objet Adds New Improved Rigid Black Material and 16 New Rigid/Rubber-Like Composites Bringing the Full Objet Range to 123 Materials

REHOVOT, Israel - Ã- Ã- Ã- Ã- Ã- Ã- Ã- - New Rigid Black material enables printing of 3D models with enhanced dimensional stability and surface smoothness. Ã- Ã- Ã- Ã- Ã- Ã- Ã- - New Objet Digital Material composites can simulate polypropylene and range of flexibilities from Shore 27 - 95. Objet Ltd., the innovation leader in 3D printing...

Read More »Grafen Chemical Industries Co. Selects Angstron Materials Graphene for Polymer Nanocomposite EMI Application

DAYTON, Ohio — Grafen Chemical Industries Co. has selected Angstron Materials' graphene material for a polymer nanocomposite application for electromagnetic shielding material. The Ankara, Turkey-based company is using both pristine and oxidized graphene products from Angstron to commercialize its EMI product for full-scale production. Grafen Chemical Industries (GCI) is a leader in the...

Read More »Arkema Launches Specialty Polyamides Med Grades for Medical Market and Appoints Velox as Exclusive European Distributor

COLOMBES, FRANCE - Arkema is committed to provide the highest quality material for the medical market; this is why almost 10 years ago Arkema began to introduce MED grades for some of its Specialty Polyamides products. An extensive range of MED grades is now available for its main product lines (PebaxÃ-® SA 01MED, RilsanÃ-® MED, and RilsamidÃ-® MED) that Arkema will sell exclusively...

Read More »

Key Considerations for Creating a Custom Cable

Consolidated Electronic Wire & Cable's new eBook, Creating a Custom Cable, reviews the key elements to designing your perfect custom-made cable solution.

Read More »Victrex Polymer Solutions Reinforces Its Focus on Composites

WEST CONSHOHOCKEN, PA, USA - Victrex Polymer Solutions has strengthened its composites business focus and has established a worldwide task force to offer an array of technical resources to assist engineers both at the processor and end-user level in order to address specific requirements within the composite area. The pressure to reduce weight, enhance reliability and durability, reduce...

Read More »

Thermoplastic Carbon Fiber Composites enhance medical components.

Stock shapes made using chemical-resistant and radiolucent TECATEC series consist of thermoplastic matrix and woven fabric of carbon fiber bundles. TECATEC PEEK CW50 is manufactured using matrix polymer VICTREXÃ-® PEEK(TM), which is then compressed with laminated woven carbon fabric mats. Also available, TECATEC PEKK CW60 consists of polyetherketoneketone matrix (PEKK) laminated with 60%...

Read More »Advanced Composite Group Ltd. and Integran Technologies Win JEC 2011 Composite Innovation Award - Equipment Category

Advanced Composites Group Ltd. (ACG), part of Umeco Composites Structural Materials (UCSM) - a Division of Umeco plc, along with Integran Technologies Inc., a world leader in Nanovate nanometal materials, have won the JEC 2011 Composite Innovation Award - Equipment Category for Carbovar - Nanovate -NV surface composite tooling. The innovation combines the hardness, durability and damage tolerance...

Read More »

Mitsuya's PrePreg Sheets Made with Victrex APTIV(TM) Film, Thinner than Traditional Carbon Fiber Composite Materials

Tokyo - Victrex Japan, Inc, a subsidiary of Victrex plc, an innovative leading manufacturer of high performance materials, including VICTREXÃ-® PEEK(TM) polymer, VICOTEÃ-® Coatings and APTIV(TM) films, announced that Mitsuya, a company developing carbon fiber composite materials, has developed a prepreg sheet with thinner layers than a traditional one by using Victrex's APTIV Films....

Read More »

Thermoset Composites withstand tough environments.

Comprised of 4 grades, NP193 series features blend of aramid fabric substrates impregnated with various resins. While NP193E uses high-temperature epoxy resin for wear resistance, NP193M uses melamine resin for corrosion resistance. Use of high-temperature phenolic resin system with woven aramid fiber/glass fabric imbues NP193P with mechanical strength, while NP193PM combines high-temperature...

Read More »

Complete Water Solutions Offers Wide Range of Water Treatment Equipment

Complete Water Solutions provides full installation tailored to your water treatment needs. Check out the video to learn more.

Read More »