Powdered Antifoam will not clog or freeze.

Type TPA works in industrial and food processes to knock down foam. Made from silicone on sodium acetate base, free flowing non-toxic powder is totally water dispersible, has non-hygroscopic properties that prevent it from lumping, and cannot freeze or separate on standing. Users may add it directly to foaming systems or specialty formulators can pre-blend antifoams with other solid products....

Read More »

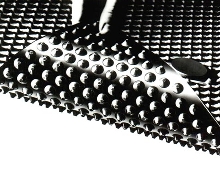

Industrial Mats are designed for hard use.

Knobby Rubber Mats, available in both black and white, feature knobs that allow for circulation of air or liquids with minimum of rubber in contact with floor. Available in 18x25 in., 21x21 in., and 21x27 in. sizes, mats have die-cut holes for hanging and drying. They are used in processing plants to protect stainless steel valves, pumps, and fittings while cleaning and repairing. White mats are...

Read More »

Fabricated Rotary Retorts have support wheels and brackets.

Fabricated replacement batch retorts are used in carburizing and hardening furnaces used by manufacturers of ball and roller bearings, chains and fasteners. Fabricated from wrought stainless steel, retorts have homogeneous, small, and tight grain microstructure resistant to furnace environments. Accessories/components include front and rear wheels, front spacing wheels, rear gas inlet tubes, rear...

Read More »

Portable Batch Sifter is suitable for food and pharmaceutical.

Lightweight batch version of Flo-Thru Vibroscreen separator scalps oversize particles from small batches of bulk material being loaded into drums, blenders, process equipment and storage vessels. Sifter is available in 18, 24 and 30 in. dia. with imbalanced-weight gyratory motor. All are made of stainless steel and finished for industrial, food, dairy or pharmaceutical applications....

Read More »

Hemp: An Eco-friendly Substitute for Cotton and Petroleum-based Synthetics

To learn more about hemp's history, composition, performance, and its sustainability and cost, download this white paper now.

Read More »

Mini Flap Discs work with small air grinders.

POLIFAN(R) flap discs are available in sizes of 2 and 3 in. dia., in flat and conical styles, and in zirconia grain with grit range 24 through 120. Discs are able to grind and finish in one step, and stay aggressive throughout life of disc. Flap discs do not require backing, run cooler, and are suitable for use on all materials.

Read More »Milling Cutters work fast and efficiently.

Fix-Perfect aluminum milling cutter inserts have on-edge orientation and 34 deg positive rake angle. This geometry reduces insert edge buildup, improves tool life, and provides free cutting action that makes it possible to machine thin-walled parts. Inserts are available in uncoated, coated, and polycrystalline diamond versions.

Read More »

Reaction Vessel is stirred with magnetic-drive mixer.

PC Series pre-packaged system includes contamination-free, leakproof magnetic-drive mixers. Vessel also features support stand, bottom flush valve, drive motor, rupture disc assembly, pressure gage, full-body spiral-baffled heating jacket or electric mantle heater, cooling coil, thermowell, and sample tube. It is available in 5, 10 and 20 gal, making it suitable for pilot-scale research and batch...

Read More »Dry Air System can be placed at application.

Mini Pneudri Midas provides uninterrupted clean, dry, compressed air where needed. It incorporates high efficiency and particulate filters plus desiccant cartridge inside 1 module that lets contaminated, compressed air in and clean, dry air out. Unit is available with pressure dewpoints of -40Ã-

Read More »

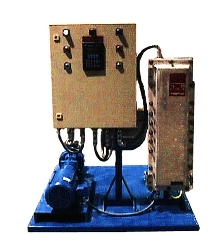

Batch Control skids into the job.

Multi-Purpose Skid batches raw materials into reactors/mixers from storage tanks or directly from tanker trucks, and batches products from reactors/mixers into storage tanks or directly into 55 gal drums. It eliminates the need for dehydrated transfer pumps and piping, raw material storage tanks, drum scales and batching equipment.

Read More »

Portable Mixer is impelled to agitate.

XPress mixers have industry-standard, off-the-shelf, NEMA motors or gearmotors with direct or gear-reduced drives. Options include sleeve or chuck shaft couplings, C-clamp or cup-plate mounting, wide range of impeller selections, and choice of 1/2 to 2 hp motors. Each has 30-day no-risk trial.

Read More »

Micro Air's Dust, Fume, Mist Collection Equipment Facilitate a Safe Work Environment

Dust, fume, and mist collectors from Micro Air promote a safer, more productive work environment. Our wide array of products are available to the industrial manufacturing sector for processes such as welding, cutting, grinding, blasting, and more. Check out our video to learn more.

Read More »