GGB Bearing Technology

Thorofare, NJ 08086

Share:

Bearings meet specifications for hydropower applications.

HPM(TM) and HPF(TM) fiber-reinforced, plastic composite bearings meet US Army Corps of Engineers' specifications for self-lubricating bearings for wicket gate applications in hydropower turbines. When subjected to accelerated wear testing under dry, wet, and low-speed, edge-loaded oscillating conditions simulating those encountered in actual hydropower turbines, bearings showed acceptable...

Read More »Composite Bearings suit hydropower applications.

HPF and HPM self-lubricating, fiber/resin bearing materials suit applications such as turbines, gates, and valves. HPF consists of filled PTFE liner bonded to fiberglass reinforced composite backing, and is available in flat and cylindrical geometries. HPM consists of bearing liner composed of PTFE and high-strength fiber winding encapsulated in epoxy resin enhanced with self-lubricating filler....

Read More »

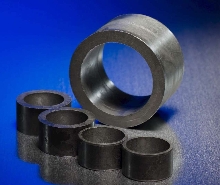

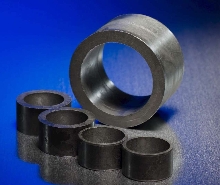

Plain Bearings withstand high loads under slow speeds.

High-Strength GAR-MAX filament-wound dry bearings are resistant to shock loads and chemicals. They withstand max static specific loads to 43,500 psi and dynamic loads to 20,000 psi. Max recommended speed is 25 fpm, and max pU factor is 40,000 psi x fps. With -148 to +320Ã-

Read More »

Solid-Polymer Bearings are optimized for dry operation.

Injection-molded EP72(TM) series plain bearings and thrust washers provide wear-resistance, low friction, and creep-resistance over temperatures up to 500Ã-

Read More »

Bearings are offered in four styles.

DP series lead-free, PTFE-based, metal-polymer plain bearings include DP20 bearings, which are suited for dry applications; chemical-resistant DP30 bearings, which are suited for automotive/industrial applications; and DP31 bearings, which provide resistance to cavitation erosion, wear, and attack by aggressive lubricants. DB(TM) bearings are constructed of cast bronze with graphite-free solid...

Read More »

Perforated Bronze Bushings increase lubrication intervals.

LD(TM) heavy-duty, wear-resistant, bronze bushings feature perforated solid strip construction. Designed for use with oil, grease, and process fluid lubricants, products capture dirt and debris in perforations. Bearings are available as cylindrical and flanged bushings as well as custom parts. Maximum load is 43,500 psi static, 17,400 psi dynamic, and 5,800 psi rotating greater than 7 fps....

Read More »

Prelubricated Bearings handle oscillating movements.

Series DS(TM) bearings eliminate fretting corrosion damage to shafts under low-amplitude oscillating movements. Bearings feature rigid steel backing to which is bonded porous bronze sinter layer, impregnated with filled acetal polymer bearing lining. Bearings withstand max static specific load of 16,000 psi. Max recommended sliding speed is 5 fps dry, 8 fps greased, and 33 fps with marginal...

Read More »Bearings meet specifications for hydropower applications.

HPM(TM) and HPF(TM) fiber-reinforced, plastic composite bearings meet US Army Corps of Engineers' specifications for self-lubricating bearings for wicket gate applications in hydropower turbines. When subjected to accelerated wear testing under dry, wet, and low-speed, edge-loaded oscillating conditions simulating those encountered in actual hydropower turbines, bearings showed acceptable...

Read More »GGB Appoints Mexican Distributor

Thorofare, N.J., November 2008 - GGB Bearing Technology has appointed Delamac de Mexico, S.A. de C.V. as a distributor for its line of prelubricated and self-lubricating plain bearings in Mexico. Partnering with Delamac, one of Mexico's leading distributors of industrial products, gives us an extended physical presence in this important market, said GGB Vice President and General Manager -...

Read More »GGB Opens Singapore Office

Heilbronn, Germany, October 26, 2006 -- GGB, formerly Glacier Garlock Bearings, has opened an office in Singapore to support its marketing and technical support activities throughout Asia. The new office will be staffed by Mathias Senghaas, the company's sales manager for Asia. The Asian market for our bearings, particularly in the automotive and industrial OEM sectors, is growing exponentially,...

Read More »Composite Bearings suit hydropower applications.

HPF and HPM self-lubricating, fiber/resin bearing materials suit applications such as turbines, gates, and valves. HPF consists of filled PTFE liner bonded to fiberglass reinforced composite backing, and is available in flat and cylindrical geometries. HPM consists of bearing liner composed of PTFE and high-strength fiber winding encapsulated in epoxy resin enhanced with self-lubricating filler....

Read More »

Plain Bearings withstand high loads under slow speeds.

High-Strength GAR-MAX filament-wound dry bearings are resistant to shock loads and chemicals. They withstand max static specific loads to 43,500 psi and dynamic loads to 20,000 psi. Max recommended speed is 25 fpm, and max pU factor is 40,000 psi x fps. With -148 to +320Ã-

Read More »

Solid-Polymer Bearings are optimized for dry operation.

Injection-molded EP72(TM) series plain bearings and thrust washers provide wear-resistance, low friction, and creep-resistance over temperatures up to 500Ã-

Read More »

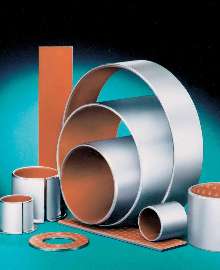

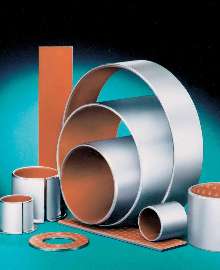

Bearings are offered in four styles.

DP series lead-free, PTFE-based, metal-polymer plain bearings include DP20 bearings, which are suited for dry applications; chemical-resistant DP30 bearings, which are suited for automotive/industrial applications; and DP31 bearings, which provide resistance to cavitation erosion, wear, and attack by aggressive lubricants. DB(TM) bearings are constructed of cast bronze with graphite-free solid...

Read More »

Perforated Bronze Bushings increase lubrication intervals.

LD(TM) heavy-duty, wear-resistant, bronze bushings feature perforated solid strip construction. Designed for use with oil, grease, and process fluid lubricants, products capture dirt and debris in perforations. Bearings are available as cylindrical and flanged bushings as well as custom parts. Maximum load is 43,500 psi static, 17,400 psi dynamic, and 5,800 psi rotating greater than 7 fps....

Read More »

Prelubricated Bearings handle oscillating movements.

Series DS(TM) bearings eliminate fretting corrosion damage to shafts under low-amplitude oscillating movements. Bearings feature rigid steel backing to which is bonded porous bronze sinter layer, impregnated with filled acetal polymer bearing lining. Bearings withstand max static specific load of 16,000 psi. Max recommended sliding speed is 5 fps dry, 8 fps greased, and 33 fps with marginal...

Read More »