AFLAS-® Fluoroelastomer Grades Receive FDA Approval for Food Contact

EXTON, Pa., July 22, 2019 — AGC Chemicals Americas, Inc. announces the U.S. Food and Drug Administration has approved three grades of AFLAS® fluoroelastomers for food contact. AFLAS 150P, 100S and 100H fluoroelastomer grades can now be utilized in equipment used in food processing applications. These AFLAS grades are ideal for components like seals, sanitary gaskets, O-rings, valve seats and...

Read More »

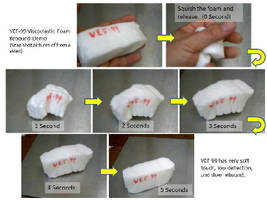

Polyurethane Foam Resin exhibits viscoelastic behavior.

Consisting of liquid polyether based polyurethane, which stays soft at very cold temperatures, VEF-99 Resin creates flexible foam for variety of custom applications. Product has very low deflection when cured and conforms to object with viscoelastic behavior. Pot life is above 30 seconds, which allows small amounts to be batched manually without dispensing machine. With mixing ratio of 1:1 by...

Read More »Conductive Silicone Rubber Gaskets feature fabric reinforcement.

Available in .020 and .032 in.Ã- thicknesses,Ã- SNE-556-R and SNE-540-R areÃ- nickel-graphite filled silicone rubber with fabric reinforcement that exhibit durability and dimensional stability.Ã- Both materials can be die cut or water jet cut into EMI shielding gaskets with narrow cross sections. While SNE-556-R consists of 65 durometer, conductive silicone used for EMI and...

Read More »Premium Spray Products - an Accella Brand - Announces Building Code Compliance of Foamsulate(TM) 220 and Staycell ONE STEP-® 255 Spray Foam Insulation System

System Meets UL 1715 and Provides Lower-Cost and Faster Installation of a Thermal Barrier ST. LOUIS - Premium Spray Products - a brand of Accella Polyurethane Systems, a leading manufacturer of spray foam insulation and coatings today announced its Foamsulate™ 220 closed-cell spray foam has recently been qualified as an interior wall insulation system which complies with the International...

Read More »

Choosing an Optimal Riot PPE Supplier: 5 Key Factors

This ebook provides 5 key factors to choosing an optimal riot PPE supplier.

Read More »

Versatile TPES for Personal Electronic Devices Provide Wide Range of Properties for Comfort, Durability, and On-The-Go Style

Teknor Apex Offers a Series of MonpreneÃ-® TPEs for Colorful and Touch-Friendly Earbuds, Cords, Grips, Cases, Wristbands, and Other Consumer Electronic Components PAWTUCKET, RI, U.S.A.Ã- – A versatile series of TPEs developed by Teknor Apex Company for consumer electronics provides the enhanced functionality, pleasing tactile properties, vivid color, and durability that are particularly...

Read More »Celanese Riteflex-® 640A TPC-ET is Plastics One 'Go-To' Material for Medical Cable and Connector Systems

Performs with High Voltage and Excels in Overmolding Florence, Ky., Sulzbach, Germany, Shanghai, PR China – RiteflexÃ-® 640A thermoplastic polyester elastomer (TPC-ET) from Celanese Corporation (NYSE: CE), a global technology and specialty materials company, is the material of choice for medical cable and connector systems produced by Plastics One Inc. Whatever we design and build, Riteflex...

Read More »

Cost Effective Protection for Submersible Components - Urethane Elastomer Series for Underwater and Extreme Weather Applications

The 20-2330 Series of low durometer urethanes, ranging from Shore A 30 to Shore A 90, is perfect for protecting electronic and other components in extreme conditions.Ã- This Series has outstanding resistance to water, good chemical resistance, and provides great electrical insulation.Ã- The products maintain their flexibility over a broad temperature range (from -40Ã-

Read More »

GOBIE-® H2O Boosts Competitive Advantage for Filtered Water Bottle with PolyOne

McHENRY, Ill. — PolyOne Corporation (NYSE: POL), a premier global provider of specialized polymer materials, services and solutions, today announced that GOBIEÃ-® H2O has selected a PolyOne specialty GLS™ TPE formulation and FDA-compliant OnColor™ colorants for its reusable filtered water bottles. The combined solution from PolyOne has helped GOBIE to enhance the consumer appeal and...

Read More »PVC Elastomer Compounds ease handling of industrial cables.

Exhibiting brittle points of -60Ã-

Read More »RTP Company to Begin Producing Nylon Bondable Santoprene TPV Compounds

WINONA, MINNESOTA, USA - Global custom engineered thermoplastics compounder RTP Company has licensed manufacturing rights from ExxonMobil Chemical for their patented Santoprene* TPV (thermoplastic vulcanizate) nylon bondable thermoplastic elastomer (TPE) product line.Ã- RTP Company has begun producing the products using the same Santoprene TPV technology to provide current users a seamless...

Read More »

Krueger Sentry Gauge Announces the Release of Two New Chemical Sight Gauge Models Designed for Aggressive Liquid Storage Monitoring

Krueger Sentry Gauge, a leader in chemical sight gauges, now offers the ultimate in aggressive liquid storage monitoring devices. From sulfuric and hydrochloric acid to bleach, and acetone, our products are designed with robust features that deliver a long and trouble-free service life. See our video to learn all about this new and innovative line of sight gauges.

Read More »