Chromalox Awarded ASME Section III N and NPT Accreditation

PITTSBURGH - ChromaloxÃ-®, a leading manufacturer of electric heat and control products, has been awarded the ASME Section III N certification for pressure-related components for designed equipment entering service in nuclear-designated areas and the NPT certification for component parts in nuclear-designated areas, such as pressurized heaters. This highly-valued certification demonstrates...

Read More »Filter Vessel Accessory adds additional eye/face protection.

Made from impact-resistant, UV-protective polymer, Splash Guard provides operators of FLOWLINE(TM) and FLOWLINE II(TM) single bag filter vessels with additional protection from liquid splash conditions in industrial environments. It secures to filter housing vessel lid and protects operators from unexpected pressurized spray and discharge. This reduces operator exposure to potentially hazardous...

Read More »Custom Processors For Specific Pharmaceutical Applications

Lee Industries, Inc. fabricates Pharmaceutical and Bio-Tech Vessels for specific applications. These vessels include specialty agitation systems, portable vessels, special CE marked vessels, and pressure vacuum units, all with custom dimensions and connections. Heavy-duty custom-designed scraped-surface agitators along with propellor mixers can be included for special mixing applications. All...

Read More »FES Systems, Inc. Reached a Manufacturing Milestone

York, PA - FES Systems, Inc. reached a manufacturing milestone this week, completing its 15,000th ASME coded pressure vessel. The first pressure vessel manufactured by FES Systems was completed in June of 1975. With 31 years of pressure vessel production, that works out to a little over nine vessels produced, on average, each week, stated Ronald Eberhard, president, FES Systems. These vessels...

Read More »

EMI Filters 101: Everything You Need To Know

In this eBook, we'll discuss everything you need to know about EMI filters, including their importance, regulatory requirements, and different types.

Read More »

PRV Kits suit high-temperature applications.

Helping to prevent meltdown, PRV (pressure reaction vessel) High Temperature Kits meet requirements for observing reactions in gases and liquids under pressure at operating temperatures above 175Ã-

Read More »

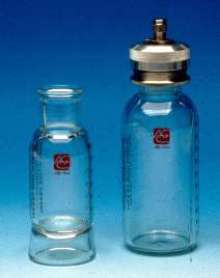

Starter Kit provides setup for pressure reaction vessels.

Suited for first time users, PRV Starter Kit includes needle valve adapter, stainless steel plug, glass vessel, and coupling. It provides everything needed to conduct observable reaction in laboratory. Chemically-inert, borosilicate glass allows safe observation of liquids and gases under pressure. Available in 3, 6, and 12 oz sizes with either regular or footed pressure vessels, kit is suited...

Read More »

Pharmaceutical Vessels are custom-designed for application.

Pharmaceutical Vessels can be designed for pressure/vacuum applications, including specialized agitation systems for up to 2,000,000 cps. They can be finished to less than 6 Ra and can include CE mark for European applications along with standard ASME design.

Read More »High-Pressure Vessels provide strength and longevity.

Monobloc-Forged Vessels are forged from single ingot and can be inspected on all surfaces to establish that no cracks are developing anywhere. They can contain presence of pressure and continue operating under repeated cyclical loading conditions without failing.

Read More »

Quartz Growth Systems suit high and medium pressure processes.

Hydrothermal Quartz Growth Systems constantly control temperature and pressure within forged pressure vessel. Average cycle time is 24 to 36 days, depending on size and quality of crystals required. Equipment is suitable to make quartz components used in a wide range of applications including oscillators, frequency filters, telecommunication systems, microprocessors, color televisions, and time...

Read More »Design Software works on pressure vessels.

PV/Designer has modeling wizard that enables engineers to create pressure vessels in compliance with standards such as ASME Boiler and Pressure Vessel Code. It has 3-D dynamic viewing with dimension display; toolbar for defining part, mesh, and thickness properties as well as common head types; capabilities for hiding areas of model using dynamic clipping planes; and parametric on-screen model...

Read More »

Precision Machining Solutions with Over 25 Years of Experience

Quality, customer service, and unbeatable value are the hallmarks of Hogge Precision. Since 1989 we have built a reputation as the go-to precision machining source, servicing many demanding industries. For CNC machining and screw machining, there are few manufacturers that can match our capabilities and expertise. See our video to learn more.

Read More »