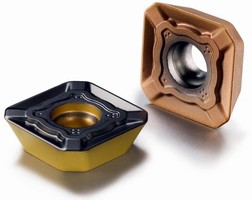

Multi-edge Milling Cutter features positive cutting action.

Featuring double-sided design with total of 14 cutting edges per insert, CoroMillÃ-® 745 is suited for face milling in large batch productions. Cutter offers 3 pitch versions: radially compensated MD pitch for when vibration is a factor, M pitch for general applications, and H pitch with higher number of teeth for higher productivity. Tilted insert positioning system in tip seat and...

Read More »

PMC-Colinet Streamlines Huge Pipe Keyway Machining with Unique Angle Head from Heimatec

Ohio manufacturer of oil field equipment saves 184 hours on one high-precision cutting tool head made of NitralloyÃ-® PMC-Colinet has a long history in the pipe and tube market, having started in 1912 and introduced the world's first carbide-tooled pipe threading machine in 1958.Ã- Today, the company is established as a primary supplier of machines to the OCTG sector.Ã- Ã- Its...

Read More »

Seco to Showcase Powerful Machining Solutions for Modern Materials at AeroDef

TROY, Mich. - At the AeroDef Manufacturing Conference and Exhibition, co-located with Composites Manufacturing 2013, taking place March 19 - 21 at the Long Beach Convention Center in California, Seco Tools will showcase several advanced tooling solutions for the efficient and precise milling and turning of difficult-to-machine aerospace materials in booth 132. Whether AeroDef attendees are...

Read More »

How to Choose the Proper Vibratory Conveyor for Your Needs

At Triple/S Dynamics, our goal is to match every single client to a conveyor system that meets their unique needs. This guide aims to provide information on the different types available to help you make the best decision.

Read More »

60 Degree Face Mill suits heavy duty machining.

With maximum cutting depth of .709 in., CoroMill 360 features wedge clamped, quick-release inserts housed in unique exchangeable cassette system whose precise location ensures accurate cutting. Heavy duty milling cutter is available in 6-20 in. dia, in close and extra close pitch design, and Arbor and CIS Arbor shank styles. Inserts are available in .748 and 1.10 in., and can be removed with one...

Read More »

Face Milling Tool features 45-

Providing face cutting with small depths of cut in steel and stainless steel, CoroMill 345 suits applications ranging from small-batch, mixed machining to high-volume dedicated production lines. It is equipped with double-sided inserts that provide 4 edges on each side, and offers full cutting edge backing and insert-seat stability through shims with strategic support islands that match insert...

Read More »Sandvik Coromant to Release Aerospace Engine Solutions Package

Fair Lawn, New Jersey, January 11, 2009 - Sandvik Coromant today announced its plan to release an Aerospace Engine Solutions Package in March 2009. The package will contain 5 standard products tailored to support the aerospace engine industry: o GC1115 - a new PVD coated grade for high temperature alloys offers improved toughness and excellent wear resistance o CoroCut angled inserts - the most...

Read More »

Dodeka(TM) Face Mills from Kennametal: Maximum Milling Performance in Carbon and Stainless Steels

(LATROBE, PA) - For demanding face-milling applications in steel, stainless steel, cast iron, ductile iron, and other materials, Dodeka(TM) inserts and cutters from Kennametal are engineered to deliver higher cutting speeds and feed rates along with extended tool life. The results are improved cutting performance and productivity across demanding materials. Compared to competitors' face-milling...

Read More »Rotary Fly-Knife Cutter

The Rotary Fly-Knife Cutter is an inline (part of an extrusion line) or offline (standalone unit) cutting unit that executes clean (chipless) accurate cuts on various post-extruded plastic and rubber profiles and tubes, such as automotive gaskets, rigid PVC irrigation tubing, and custom profiles. This unit belongs to CDS's family of Fly-knife Cutters, which employ a fly-knife wheel accommodating...

Read More »

Inserts are intended for cast iron milling operations.

Suited for machining nodular cast iron and wet cast iron, Model GC1020 has PVD coating that improves cutting speeds and wear resistance for reliability in unstable conditions. Model GC3220 has thick protective coating that helps dry machining of grey cast iron, and is designed for shoulder milling and face milling.

Read More »

Material Handling Solutions from Global Leader in Rubber & Urethane Power Transmission

Megadyne's QST polyurethane timing belts take up less space and guarantee a lower noise level than chain and other traditional material handling belts. Check out our video to learn more.

Read More »