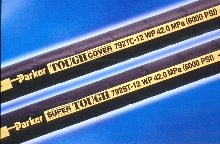

High Pressure Hoses handle up to 6,000 psi.

Models 792TC and 792ST spiral hoses exceed SAE 100R15 specifications, making them suitable for hydrostatic transmissions, power units, injection molding machinery, test stands, and mining equipment. Both are constructed of 6 spirals of high-tensile steel wire reinforcement, have oil-resistant high-Nitrile inner tube that is compatible with hydraulic fluid, and have abrasion-resistant covers with...

Read More »

Hoses are ideal for half-bend radius applications.

Models 351TC and 351ST abrasion-resistant hoses, designed for 1/2 SAE 100R1 minimum bend radius applications, are available with MSHA-accepted Tough Cover or Super Tough polymeric cover. Both offer 4,000 psi constant working pressure in sizes that range from 1/4 in. to 3/4 in. I.D. They are constructed of oil-resistant, Nitrile-based synthetic rubber tube, with 2 braids of high-tensile steel wire...

Read More »

Metal Stamping and Forming for Your Automotive Applications

Check out this white paper to learn about the advantages of metal stamping over other forming techniques for automotive parts.

Read More »

Clear Clogged Drains Faster with General Pipe Cleaners' Kinetic Water Ram

The Kinetic Water Ram by General Pipe Cleaners clears out clogged pipes quickly using kinetic energy. The Ram is so simple to operate, anyone can use it. Check out the video to learn more.

Read More »