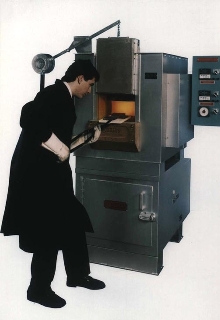

Dual Furnace saves space.

Model AY Controlled Atmosphere Hardening Furnace can be combined with Model HT Recirculating Air Tempering Furnace in dual furnace configuration. Model AY furnace can be used with Diamond Block system of atmosphere control, a carbonaceous box that automatically provides protective atmosphere for tool steel hardening. Model HT offers recirculating air system providing efficient heat transfer and...

Read More »

Electric Bench Furnace suits heat-treating applications.

No. 886 dual-chamber furnace comprises upper chamber with operating temperature to 2200 deg F and lower chamber with operating temperature to 1250 deg F. Nickel-chrome wire coils, supported by ceramic plates, provide 40 kW of heat (20 kW in each chamber). Each chamber has 6 in. thick walls made from 2 in. of 2300 deg F ceramic fiber and 4 in. of block insulation. Both chambers have individual...

Read More »

Infrared Furnaces have reduced power consumption.

S and TFA Series Infrared Furnaces can heat up to 1000Ã-

Read More »Choosing the Right Cleanroom Equipment Supplier

This whitepaper discusses key considerations for choosing a cleanroom equipment supplier: what to look for, types of cleanrooms & their standards.

Read More »

Optimize Your Workforce with Weavix™ by PK Industrial

The Weavix™ platform takes productivity, quality, and visibility to a new level by providing better communication and real-time KPIs. Check out the video to learn more!

Read More »