General Purpose Box Furnaces suit various applications.

Ranging in size from 6 x 6 x 6 in. to 24 x 24 x 48 in., Series 7000 suits hardening, drawing, preheating, annealing, brazing, normalizing, and special applications under air atmosphere. Construction, designed for minimum heat loss, includes reinforced welded sheet metal shell as well as multi-layered firebrick and mineral block insulation. Enabling operating temperatures from 1,850 to 2,350Ã-

Read More »Centorr Vacuum Industries Builds 28 Meter Vacuum Furnace for Nuclear Power Station Tubing

Nashua, NH, 12 January 2009 Centorr Vacuum Industries announced it is completing the manufacture of a 28 meter long precision vacuum annealing furnace for straight tubes and U-tubes for use in Nuclear Power Stations. The furnace is based on proven designs previously sold worldwide by CVI for vacuum tube annealing and degassing. The company has been providing this type of furnace to the nuclear...

Read More »11,000 LB Weldment Heat Treated

Solar Atmospheres, Souderton, PA, recently heat treated two 4140 (chromium molybdenum) steel weldments, each weighing 11,000 lbs. Using a 12 foot long horizontal loading Solar Manufacturing furnace with a 50,000 lb. capacity, Solar normalized and tempered the weldments to achieve specific yield strength, while minimizing distortion, through controlled heating and cooling. The weldment dimensions...

Read More »

Metal Melting Furnace suits applications up to 1,000-

Buzzer furnace melts low temperature white and soft metals including pewter, babbitt, tin, solder, bismuth, lead, zinc, and die casting alloys. It is available with digital controls, high limit safety, and comes in 5 standard sizes with lead capacity from 160 to 2,700 lb. Customization includes special sizes, tilting furnaces, high temperature metals, and bottom drain spout units.

Read More »

Understanding Lights Out Manufacturing

This white paper gives an overview of understanding lights out manufacturing.

Read More »

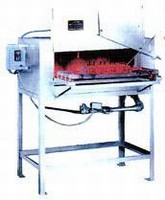

Roll Out Furnace targets automotive repair market.

Available in 4 standard sizes, Buzzer 450 to 1,350Ã-

Read More »ADMET Offers UTM Accessories - Extended Travel Extensometer and Environmental Chambers

NORWOOD, Mass. - Nov. 27, 2007 - ADMET Inc., a provider of integrated materials testing systems, supplies a full range of Universal Testing Machines (UTMs) and accessories, including specialty extensometers and environmental chambers for testing specimens under controlled conditions. The company today announced new additions to its extensive accessories catalog. Among the new accessories, ADMET...

Read More »AirLoc Wedgmount Levelers and Damping Pads Provide the Precision Positioning and Vibration Isolation Required for Delicate Kayex Crystal Growing Equipment!

Kayex develops and manufactures crystal growing equipment for the semiconductor and photovoltaic materials industry. These high-temperature, vacuum furnaces are used to grow single crystal silicone ingots. The ingots are then sliced into wafers that are used as the substrate for either computer chips or high efficiency solar cells. This is a process which obviously requires precision and reduced...

Read More »Solar Atmospheres at IMTS Show

Solar Atmospheres, with plants in Eastern and Western PA, will offer two new and unique heat treating capabilities at IMTS 2006 in Chicago. Located at booth B-6423, Solar is introducing the largest load capacity vacuum heat treating in the world. Another unique and new service offer is the insitu vacuum carburizing technology to case harden and improve part wear life. Outstanding furnace load...

Read More »CEC is Awarded a Contract for a Second CleanCast-® Implementation at Superior Industries

Kennesaw, GA (October 31, 2006) - Superior Industries, one of the world's largest manufacturers of cast aluminum wheels, has contracted with CEC to integrate and automate T-6 heat treatment with the upstream casting and downstream machining process. This highly innovative new plant features CEC's CleanCastÃ-® foundry technology. Phase I of this endeavor began in April 2005 when Superior...

Read More »

Vacuum Furnace provides thermocouple control to 1,000-

Model CVF 1000 Ultra High, Clean Vacuum Furnace is designed for degassing and conditioning components that are used inside vacuum environment to reduce outgassing and pumpdown time. It features 24 in. wide x 30 in. high x 24 in. deep SS water cooled chamber with hinged front door, high vacuum cryogenic pumping, molybdenum and inconel hot zone, full computer control with data logging, and...

Read More »

The Carbontec System: A Smarter Way to Heat Your Buildings

Carbontec's paper-thin radiant heating systems reduce energy consumption costs by warming the building surfaces instead of controlling air temperature. Check out our video to learn more.

Read More »