Fluid Bed Processor offers several operational capabilities.

Circular, vibratory fluid bed dryers, coolers, and moisturizers are offered with Air-Lift device that facilitates disassembly, cleaning, and inspection of fluid bed processing chamber. Available on fluid bed processors in diameters from 18-84 in., self-contained system is comprised of circular fluid bed processor, heating/cooling/moisturizing unit, blower, and cyclone separator on one skid....

Read More »

Stainless Steel Cylinder is available in 8 bore sizes.

With round, smooth bodied design, Repairable Stainless Steel Cylinder (RS Series) suits washdown environments and other applications that require all stainless steel design. Product, available in 1Ã-½, 2, 2Ã-½, 3Ã-¼, 4, 5, 6, and 8 in. bore sizes, meets USDA and 3-A sanitary specifications and is suited for use in food industry. It can also be accepted for use in dairy plants approved...

Read More »

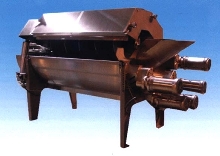

Centrifuge handles small-capacity processing.

Suited for use in vegetable oil refining and biodiesel production, RSC 30 Centrifuge offers self-cleaning, gas-tight operation. Output capability is 50 tons/day or 5,000 lb/hr.

Read More »

Tumbling Machines use light to decontaminate food.

UVC Tumbling Machines incorporate rotating drum or screw conveyor that gently lifts and tumbles product to ensure exposure of all surfaces to germicidal UVC energy. Shatter-resistant, plastic-sheathed UVC Emitters(TM) prevent chance of glass contamination from tube breakage. Lights kill or inactivate mold, yeast, viruses, and bacteria. They produce no ozone or residues, and will not chemically...

Read More »

Why You Need a Dehumidification System in Your Residential Swimming Pool Room

Learn about the role of dehumidifiers in indoor pool applications.

Read More »

Swing Check Valve handles food-grade material.

Model 3030 SQ 3 in. valve, for flow reversal prevention in dry-bulk transfer carriers, protects food-grade and sensitive contents at temperatures up to 350Ã-

Read More »

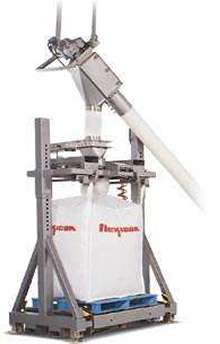

Bulk Bag Filler is USDA accepted.

Twin-centerpost(TM) unit provides product contact surfaces that are constructed and finished in compliance with 3-A standards. Available with primary bag filling components and material delivery system, filler is constructed of 304 stainless steel. It is equipped with manual fill-head height adjustment, pneumatically retractable bag hooks, inflatable cuff, and feed-chute outlet port. Unit is...

Read More »

Peeler utilizes dry peel operating principles.

U-Bed High Speed Peeler offers roll speeds up to 1000 rpm. Peel is flushed out of rotation brushes by centrifugal force, reducing need to use water. Two-way cover lifts with pneumatics and opens from either side for cleaning access. U-Bed processes all root crops including carrots, dry scrubbing potatoes after steam peeling, and potato chips for fresh product peeling.

Read More »

ISO-Certified Precision Machining and Contract Manufacturing Services from DFF

DFF is an industry leading contract manufacturer specializing in medium to high production precision machined components and electromechanical assemblies. Our 100 CNC machining centers and design-assist capabilities ensure our customers' needs are always met. Check out our video to learn more.

Read More »