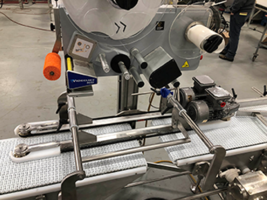

Split Conveyor 'Suspends' Product for Top and Bottom Print/Labeler

Winneconne, WI - Multi-Conveyor (www.multi-conveyor.com) - Multi-Conveyor recently built a this unique stainless steel 3-A Dairy sanitary wash down welded conveyor, designed to transport plastic wrapped blocks of food in conjunction with a customer supplied starwheel top and bottom labeler. See the YouTube link to this equipment below. The infeed conveyor actually splits while product is...

Read More »

Monobeam Vibratory Conveyors support food processing.

With frame made of single structural member, Iso-FloÃ-® Vibratory Conveyors offer optimized hygiene, minimizing risk of product contamination and maintaining food safety. Frame and spring arms can be tucked completely under conveyor bed. Featuring standard rotary polish within product contact zone, stainless steel bed resists bacterial attachment and biofilm formation. Standard oil-free...

Read More »Plastic Chain Conveyors support food, pharmaceutical industries.

Used as transport solution for food, packaging, and pharmaceutical industries, ConnexÃ-® plastic chain conveyors deliver flexibility and modularity needed between processing and distribution inÃ- supply chain operations. Conveyors are also available in aluminum (AL), stainless steel (SS), and powder coated steel (PC).

Read More »

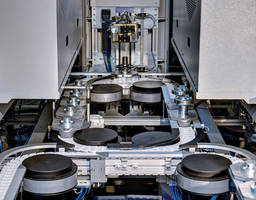

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

UNLOCKING THE HIDDEN POTENTIAL OF MANUFACTURING: How lubricants can help increase productivity and reduce total cost of ownership

This paper illustrates how manufacturing companies have successfully worked with Shell Lubricants to upgrade their lubrication and extract value by reducing TCO and improving equipment productivity.

Read More »

Unique Application Creates Innovative Ergonomic Lift Table Solution

Guelph, Ontario, Canada – In October of 2013, Pentalift was approached by a large provider of contract sterilization using gamma irradiation. The company was looking for a solution to their unique application which would pair a man lift, or work platform, with a pallet lift. Both units would need to be controlled by a single custom control panel located on the work platform, as would the...

Read More »Extendable Conveyor System lasts 15-20 years or more.

Equipped with heavy-duty drive systems, including strong chains and oversized sprocket shafts, Model 2555 requires minimal maintenance. Heavy-duty cam followers and bearings deliver durability at full extension, while protected cable runs prevent damage to wires that power and control conveyor as it moves. Exceeding parcel industry's upper limits for package volumes and weights, steel structures...

Read More »Crossbelt Sorter offers non-contact data communications.

Suited for distribution and warehouse operations, FlexSort SC3 provides precise positive sorting of poly bags, pieces, stuffed envelopes, cartons, and totes using discrete belt conveyors mounted on carriers in re-circulating loop configuration. Drive system can be configured with linear induction drive motors or with linear synchronous motors. For power and data transmission, sorter can be...

Read More »Automated Robotics, Conveyor Systems serve flat glass industry.

Robotic glass handling systems and conveyors provide accurate and smooth handling and gapping of glass to maximize throughput through ovens and coating lines. Standard and custom robotic glass handling equipment and peripherals cover glass rack loading/unloading, slotted IG rack loading, high-speed glass stacking, rack unloading with interleaf removal, box packing with interleaf, and solar module...

Read More »PCB/Backplane Handling Equipment manage large and heavy loads.

Using 10 mm wide positive track ESD belts, capped to 3 mm edge contact, conveying solutions can transport up to 40 lb PCB and backplane panels that range up to 30 in.Ã- wide and up to 36 in.Ã- long. Other solutions include vertical buffering, turns, accumulation, and more.

Read More »

Davron Ships Three Fully Assembled Continuous Conveyor Ovens to China

Chattanooga, Tenn.Ã- – Davron Technologies, Inc. manufactured three electric infrared continuous conveyor ovens and shipped them fully assembled to a client in China. The continuous conveyor ovens, model DTI-991, were designed to cure automotive disc brake coatings. Featuring three heating zones powered by three infrared panels of approximately 30,000 watts each, the DTI-991 continuous...

Read More »

Solve Any Large-scale Water Control Problem with the Aqua Dam Flood Barrier

Aqua Dam is the ultimate solution for large-scale water control projects. It combines lightweight, large size, and portability all in one innovative product. To learn more about the uses, and applications of Aqua Dam, or to see it in action, check out our new video to get all the details.

Read More »