Grooved Rolls Remove Trapped Air

Unique roll grooving releases air between web and roll to eliminate web slip. (Neenah, Wis.) - Precision machined idlers with custom groove patterns eliminate trapped air that causes web slipping. Machined surface patterns ideal for eliminating trapped air include the spiral V groove, the herringbone groove, the diamond knurl and the micro groove. Grooves are available on all Webex rollers...

Read More »

Conveyor Damage: A Perennial Problem Solved with New Technology

Huntington, WV February 27, 2008 The belt conveyor created a revolution in the mining industry as it replaced more labor-intensive forms of haulage and reduced the cost per ton of handling bulk material. From the beginning, though, belt damage occurred when the material was loaded onto the conveyor belt. Jagged lumps of falling material perforated and abraded the belt. Further, alien materials...

Read More »Conveyor Components suit medium-duty applications.

Drive and idler units have compact design and are suited for integration into machines in order to create smooth interfaces with infeed and outfeed conveyors. Designed for FlexLink XL and XM conveyor systems, products can handle light to medium conveyor loads at moderate to medium speed. They include directly driven drive wheel as well as slots to facilitate accessory attachment.

Read More »

Idlers target hard rock and mining applications.

Available for 36-96 in. belt widths, Series 100 CEMA E Idlers feature 1Ã-¾ in. solid shaft, Ã-¼ in. steel centerstands and endstands, as well as heavy-duty rollers with 6 and 7 in. roll diameter and Ã-¼ in. roll thickness. Precision-sealed, 40 mm ball bearings have nylon labyrinth lubricated seal with cover shield that retains grease in bearing cavity, excludes contaminants, and...

Read More »

Everything You Need to Know About E-Textiles

This ebook provides an in-depth overview into everything you need to know about E-Textiles.

Read More »

Idler Line is built to CEMA B-E specifications.

Heavy-duty CEMA E, engineered for reliable operation in abrasive hard rock and mining applications, features 40 mm, double-sealed bearing; nylon seals; and 1Ã-¾ in. nominal shaft. Available in 6 and 7 in. roll sizes with thickness of 7 gauge (6 in. rollers), product features powder coated finish and external seals for additional bearing protection.

Read More »

Idlers offer direct interchange with Universal-style rolls.

Series 40 features 4 in. diameter rolls, replaceable end rollers, universal center bracket, and heavy-duty die-cast center stands. Available in 20, 30, 45, and 60Ã-

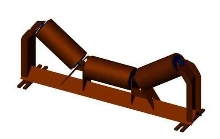

Read More »Training Idler keeps conveyor belts on track.

Arch Tri-Return Training Idler employs concave arrangement of 3 idler rolls on center pivot, supporting belt with 6 bearings, to automatically correct misalignment. It consists of one horizontal center roll and 2 outer rolls, positioned at descending angles, allowing idler to fit full cup of belt. Rubber cover on rolls reduces buildup, increases life of rolls, and speeds reaction time.

Read More »

Come Alive Organics' Premium Organic Agave Provides a Healthier Choice

Come Alive Organics distributes all-natural, proprietary flavored agave for the food and beverage industry while helping children across the globe. Learn more about our agave products and our one sweet cause in this video and two-page PDF.

Read More »