One Part, Toughened Epoxy for Dam-And-Fill Encapsulation

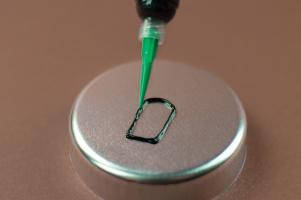

Master Bond Supreme 3DM-85 is a no-mix, non-solvent-based, one-component epoxy. This thixotropic paste material was formulated to serve as the damming compound in dam-and-fill encapsulation applications. It can also be utilized for bonding and sealing, especially where no flow is needed since the material cures in place and will not run or slump. The compound requires a relatively low heat cure of 85°C for 2-3 hours, is thermally conductive and electrically non-conductive.

Supreme 3DM-85 is designed for heat-sensitive components that cannot withstand high temperatures for curing. The fact that it is not premixed and frozen gives it an advantage in production situations where freezer storage may not be practical. Also, there are no special shipping requirements,” says Senior Product Engineer Rohit Ramnath. As a toughened system, Supreme 3DM-85 resists rigorous thermal cycling. It is a reliable electrical insulator and features a thermal conductivity of 5-10 BTU•in/ft2•hr•°F [0.72-1.44 W/(m·K)]. It plays an important role in facilitating effective heat dissipation and preventing overheating, especially in densely packed electronic assemblies. The epoxy maintains a Shore D hardness of 75-85, offers excellent damp heat resistance, and has a good physical strength profile.

Supreme 3DM-85 forms strong bonds with an extensive range of substrates commonly found in electronics and semiconductors. Substrates include metals, composites, ceramics, silicon, and a wide array of plastics. As a single-part system, it is easy to handle and offers unlimited working life at room temperature. It is opaque black in color and can be applied manually or automatically. Serviceable from -100°F to +350°F [-73°C to +177°C], Supreme 3DM-85 is available for use in syringes and jars.

Master Bond Adhesives for the Electronics Industry

Supreme 3DM-85 is a toughened, one-part system developed as a damming compound for dam-and-fill encapsulation. It is also useful for bonding and sealing purposes, where heat curing above 200°F is not possible. Read more about Master Bond’s specialized adhesives for the assembly of electronic devices at https://www.masterbond.com/industries/adhesives-assembly-electronic-devices or contact Tech Support. Phone: +1-201-343-8983 Fax: +1-201-343-2132 Email: technical@masterbond.com.

Contact:

James Brenner

Marketing Manager

Email: jbrenner@masterbond.com

Tel: +1-201-343-8983

Fax: +1-201-343-2132

MASTER BOND INC.

154 Hobart Street

Hackensack, NJ 07601-3922

Web: www.masterbond.com