Bal Seal Engineering, Inc.

Foothill Ranch, CA 92610

Polymer Seals withstand harsh conditions.

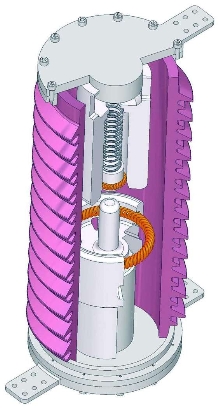

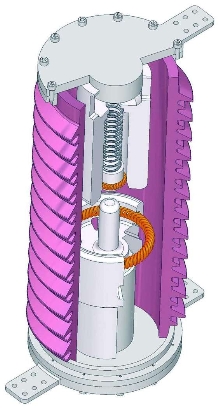

Made of formulated, blended PTFE or other engineered polymer compounds, Polymer Seals employ pressure-energized canted-coil spring technology, which enables near-constant contact force over wide range of working deflection. Metal locking ring pressed into housing of each seal minimizes diametrical seal shrinkage. Seals withstand high temperatures, pressures, and velocities as well as abrasive and...

Read More »

Springs are suited for medium- and high-voltage switchgear.

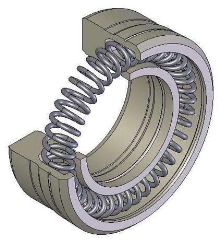

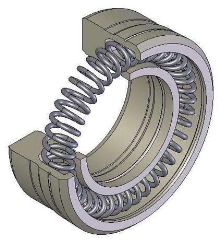

Rated for current to 1,800 A, BalContact(TM) Springs utilize canted-coil spring design that enables near-constant contact force over working deflection range. Spring lifetime is rated at over 10,000 cycles, and products are constructed to withstand harsh environments. They enable steady current transfer, even in applications where torquing, misalignment, vibration, and shock are present. In...

Read More »

Seals protect equipment in drilling environments.

BAL(TM) Seal series U-13X, U-14X, and KS13X ensure down-hole data logging tools remain isolated from harsh, abrasive drilling environments. Sealing technologies U-13X and U-14X withstand 25,000 psi down-hole pressure and 150 psi differential sealing pressure in oil drilling operations, while KS13X suits press-in metal locking ring retention systems. Constructed of filled PTFE seal material, each...

Read More »All About Polymers: A New Site Resource for Seal Material Data

We’re an engineering company, and we share your love for breaking things down to their most essential elements. After all, what better way is there to learn about form, function, and potential performance limitations? That engineering mindset is what motivated us to create and launch a new website feature dedicated to seal materials. Specifically, the premium polymers we use to make our Bal...

Read More »Kaman Completes Acquisition of Bal Seal Engineering, Inc.

Bloomfield, Conn.– Kaman Corp. (NYSE:KAMN) announced today that it has completed the previously announced acquisition of Bal Seal Engineering, Inc. (“Bal Seal”), a leader in the design, development, and manufacturing of highly engineered products including precision springs, seals, and contacts. With this acquisition, Kaman has significantly expanded its portfolio of engineered products and...

Read More »New Bal Seal Website Helps Designers Find Solutions Fast

Foothill Ranch, Calif., May 22, 2019 – Bal Seal Engineering, Inc., a leading global designer and manufacturer of custom sealing, connecting, conducting, and EMI/RFI shielding components, today announced the launch of its new website at www.balseal.com. The mobile-friendly site, which features streamlined product performance data, real-world application examples, and an expanded technical...

Read More »Bal Seal Engineering Updates Rotary Seal Catalog

Foothill Ranch, Calif. – U.S.A. – September 17, 2019 – An updated technical catalog published by Bal Seal Engineering provides designers with detailed information about how spring-energized seals can be used to address rotary sealing challenges. The 32-page catalog, titled “Bal Seal® Spring-Energized Seal Solutions for Rotary Applications,” describes how the company’s broad range of...

Read More »Bal Seal Addresses Analytical Pump Pressures in New Tech Article, Podcast

Resources Navigate Engineers Through 20KPSI Pressure Challenges Foothill Ranch, Calif. - March 1st, 2012 - With a technical article slated for publication in two major magazines next month, and a podcast on its Website. Bal Seal Engineering is providing designers of liquid chromatography pumps with techniques to meet new operating pressure demands of 20KPSI and higher. Bal Seal, a global provider...

Read More »Polymer Seals withstand harsh conditions.

Made of formulated, blended PTFE or other engineered polymer compounds, Polymer Seals employ pressure-energized canted-coil spring technology, which enables near-constant contact force over wide range of working deflection. Metal locking ring pressed into housing of each seal minimizes diametrical seal shrinkage. Seals withstand high temperatures, pressures, and velocities as well as abrasive and...

Read More »New M-Series Product Spearheading Bal Seal Product Display at Upcoming Medical Manufacturing Tradeshows

Foothill Ranch, Calif., Sept. 9, 2005 - Bal Seal Engineering, provider of industry-leading solutions that incorporate material science and canted-coil spring technology, announces that its new M-Series (molded contact products) will be a highlight of the company's product display at upcoming medical device/manufacturing tradeshows and conferences. The patented M-Series product, with its...

Read More »

Springs are suited for medium- and high-voltage switchgear.

Rated for current to 1,800 A, BalContact(TM) Springs utilize canted-coil spring design that enables near-constant contact force over working deflection range. Spring lifetime is rated at over 10,000 cycles, and products are constructed to withstand harsh environments. They enable steady current transfer, even in applications where torquing, misalignment, vibration, and shock are present. In...

Read More »

Seals protect equipment in drilling environments.

BAL(TM) Seal series U-13X, U-14X, and KS13X ensure down-hole data logging tools remain isolated from harsh, abrasive drilling environments. Sealing technologies U-13X and U-14X withstand 25,000 psi down-hole pressure and 150 psi differential sealing pressure in oil drilling operations, while KS13X suits press-in metal locking ring retention systems. Constructed of filled PTFE seal material, each...

Read More »