I-TECH International Corp.

Pompton Plains, NJ 07444

Share:

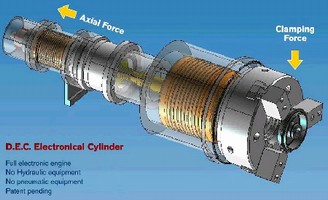

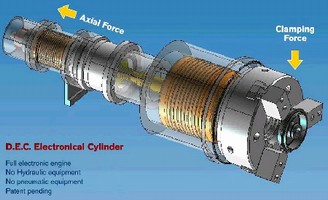

Actuation System provides automatic clamping force.

Delivering clamping force required for rotary and fixed workholding devices, CMT Electronic Actuation System uses motor and ball screw arrangement that transfers rotary movement into axial movement. Used on lathes and other machinery, system can change clamping force instantaneously as part of CNC program. It clamps with maximum force required to hold work piece and not deform work while...

Read More »

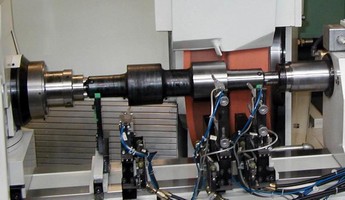

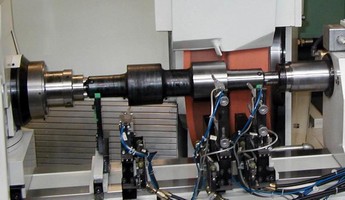

Grinding Workpieces Hardened up to 63 HRC with High Performance Face Drivers and Live Centers

Grinding with Tecnologie FRB face drivers and live centers has many advantages. The most important is that you can obtain a substantial reduction in machining time, which in some cases is over 50% compared to a conventional grinding operation with chuck, driving dogs or collets. Thanks to a face driver it is possible to machine the entire workpiece in a single clamping as the face driver do not...

Read More »

Actuation System provides automatic clamping force.

Delivering clamping force required for rotary and fixed workholding devices, CMT Electronic Actuation System uses motor and ball screw arrangement that transfers rotary movement into axial movement. Used on lathes and other machinery, system can change clamping force instantaneously as part of CNC program. It clamps with maximum force required to hold work piece and not deform work while...

Read More »

Grinding Workpieces Hardened up to 63 HRC with High Performance Face Drivers and Live Centers

Grinding with Tecnologie FRB face drivers and live centers has many advantages. The most important is that you can obtain a substantial reduction in machining time, which in some cases is over 50% compared to a conventional grinding operation with chuck, driving dogs or collets. Thanks to a face driver it is possible to machine the entire workpiece in a single clamping as the face driver do not...

Read More »