Actuation System provides automatic clamping force.

Share:

Press Release Summary:

Delivering clamping force required for rotary and fixed workholding devices, CMT Electronic Actuation System uses motor and ball screw arrangement that transfers rotary movement into axial movement. Used on lathes and other machinery, system can change clamping force instantaneously as part of CNC program. It clamps with maximum force required to hold work piece and not deform work while maximizing spindle rotational speed.

Original Press Release:

CMT Tubertini SRL Is Proud To Announce The Release Of An Electronic Actuation System

CMT Tubertini SRL is proud to announce the release of an electronic actuation system, which will deliver the clamping force required for rotary and fixed workholding devices.

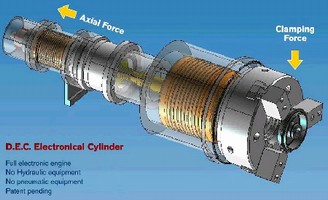

The latest offering from CMT Tubertini is an innovative electronic system designed to be used on lathes and other machinery where an automatic clamping force is required. This system using a motor and ball screw arrangement transfers the rotary movement into an axial movement. This axial movement used as a draw bar would be to open and close workholding devices.

There are some unique advantages to this electronic system that can not be reached with conventional hydraulic or pneumatic systems. The clamping of shaft type work with differing outside diameters requires differences in the workhead spindle speed for optimum use of the machine tool. The CMT electronic system gives the real-time advantage of changing the clamping force needed instantaneously as part of the CNC program. The CMT electronic system offers the ability clamp with the maximum force required to hold a work piece and not deform the work, while at the same time allowing the maximizing of the spindle rotational speed. For multiple part type operations the needed clamping force for any given work piece is a function of the size of the work and the needed speed of the spindle. This force setting, if changed was one additional step taken during the setup of the machine. Now with the electronic CMT system adjustment can be made through the CNC, during the program call-up. There is both the safety of having enough force to hold a give part and flexibility of reducing the force when a high force is not needed resulting in less wear of workholding components. Additional the CMT electronic system will eliminate the need for the hydraulic power pack resulting in an economic saving.

CMT Tubertini products are offered in North America by I-TECH International Corp. Please contact info@itechcorp.us for additional information.

I-TECH International Corp.

P.O. Box 606

Pompton Plains, NJ 07444

Ph 973-248-0099

Fax 973-248-0950

Contact: Jon Celio

Sales & Eng. Mgr.