Grinding Workpieces Hardened up to 63 HRC with High Performance Face Drivers and Live Centers

Share:

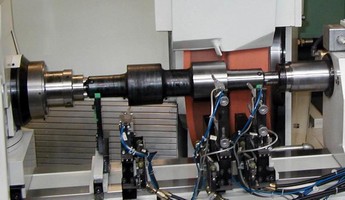

Grinding with Tecnologie FRB face drivers and live centers has many advantages. The most important is that you can obtain a substantial reduction in machining time, which in some cases is over 50% compared to a conventional grinding operation with chuck, driving dogs or collets.

Thanks to a face driver it is possible to machine the entire workpiece in a single clamping as the face driver do not interfere with the working area. No chucks, no driving dogs or collets are required as with these systems a portion of the outer diameter of the shaft is engaged and a second operation to finish the workpiece is required (removing, reversing and rechucking the part).

Furthermore, use of Tecnologie FRB live centers and face drivers allow a higher workpiece peripheral speed so that there is a reduction in contact wheel time. The result is a workpiece with better tolerances, surface finish and a reduced machining time.

Tecnologie FRB will introduce their equipments for turning and grinding applications during IMTS 2006 Show in Chicago, 6th -13th September 2006 I-Tech at booth # B-6668.

Tecnologie FRB was founded in 1960 by Eng. Romano Franceschelli who invented first the live center with load distribution and then the face driver with a self compensating system of the driving pins, completely mechanical. Today TECNOLOGIE FRB set the standard on face driving applications.

In the U.S., Tecnologie FRB products are sold and serviced by I-TECH Grinding and Manufacturing Solutions, a partnership of leading Italian grinding machine manufacturers. The U.S. Sales and Service facility is located at 231 West Parkway, Pompton Plains, New Jersey, 07444. web site www.itechcorp.us Their phone number is 973-248-0099. Manufacturer website is www.tecnologiefrb.com