OPEN MIND Technologies USA Inc.

Unit 3

Needham, MA 02492

New hyperMILL 2019.2 CAD/CAM Software Enables More Secure Programming with Reduced Process Time

Features include high-precision 3D finishing, 5-axis tangent machining, high-performance turning, and CAD-for-CAM technologies. Utilities streamline CAM programming and provide tested and proven methodologies. Multiple faces can be joined into one face with controlled ISO orientation.

Read More »

New Advanced hyperMILL CAM Software Offers Three Modules for Finishing, Roughing and Drilling

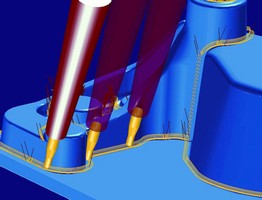

Enables the use of conical barrel cutter technology to reduce cycle times over 90%. Calculates toolpaths independently of machine and controller. Ideal for planar, ruled and curved surfaces found in complex 5-Axis components.

Read More »OPEN MIND's hyperMILL-® CAM Solution Certified by Autodesk

From design to machining Wessling (Germany) – hyperMILLÃ-®, the CAM solution from OPEN MIND Technologies AG, is fully compatible with Autodesk Inventor, as officially confirmed once more following certification by Autodesk Inc. for hyperMILLÃ-® and the latest release of Autodesk Inventor 2014. The seamless integration of hyperMILLÃ-®, including data associativity, allows continuous...

Read More »OPEN MIND Technologies at Tire Technology Expo 2014

hyperMILLÃ-® tire module push machines to the limit Wessling (Germany) — OPEN MIND Technologies AG, one of the leading CAD/CAM software developers, is set to present its solutions for the tire industry at Booth 4050 at Tire Technology Expo 2014 in Cologne, Germany, from 11 to 13 February 2014. The tire module was once again significantly extended in the current version of the...

Read More »

OPEN MIND Extends Partnership with PTC-®

Wessling, Germany, June 4, 2007 - hyperMILLÃ-®, the user-friendly 2-D, 3-D, HSC, and 5-X CAM system, is now available integrated within Pro/ENGINEER Wildfire from Parametric Technologies Corp. As OPEN MIND Technologies AG has recently renewed its membership in the PTC Partner Advantage(TM) Program, this partnership makes OPEN MIND's technology-leading hyperMILL software available to...

Read More »

The CAM Software Hypermill-® - Easy to Use, Versatile in Application!

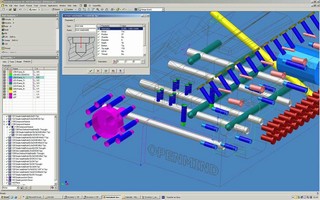

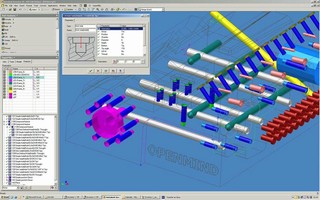

From 2D feature machining to 5-axis simultaneous milling, hyperMILL covers a wide range of machining strategies for diverse manufacturing tasks. At the OPEN MIND Technologies AG booth (D-3306), visitors to IMTS 2006 will have the chance to see exactly how flexible manufacturing can be with hyperMILL. There will be more than 1,200 exhibitors at IMTS 2006 that is taking place at McCormick Place in...

Read More »

OPEN MIND Technologies to Demonstrate HyperMILL-® v9.5, Booth D-3306

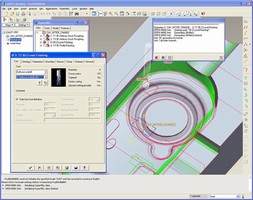

This updated version of hyperMILL has many new and improved functions including extended Feature Technology and a significant overhaul of multi-axis cutter orientation control. hyperMILL's Feature Technology allows users to standardize programming processes for parts with recurring or similar geometries for 2.5D through 5-axis applications. Feature Recognition adds intelligence to native or...

Read More »

OPEN MIND's hyperMILL-® Certified for Autodesk Inventor 11

Autodesk (San Rafael, CA) has officially certified hyperMILLÃ-® CAM software from OPEN MIND Technologies for version 11 of Autodesk InventorÃ-®. With this certification, Autodesk guarantees that third-party applications are perfectly compatible with Inventor, assuring maximum reliability and performance. OPEN MIND Technologies AG has been participating in the Autodesk Inventor Certified...

Read More »

Open Mind Demonstrating hyperMILL-® Feature Technology at Moldmaking Expo

OPEN MIND will present its hyperMILLÃ-® CAM software at the Moldmaking Expo in Novi, MI on April 25 and 26. The software is applied to 2.5D through 5-axis milling and drilling, and is supported by a strong surface/solid hybrid modeler. Feature Technology is becoming an increasingly important technical feature that can help you organize and add intelligence to CAD models for use with...

Read More »

CAM Software features automatic collision avoidance.

HyperMILLÃ-® v9 multi-axis CAM software provides functions that include stock roughing with automatic feedrate reduction, stock management, definition of milling and stop surfaces, and machine and material removal simulation. Feature technology aids in processing existing machining and geometry information to minimize required programming in CAM system. Bidirectionality between CAD model and...

Read More »Tech Soft 3D and OPEN MIND Collaborate on Powerful CAM Solutions

With HOOPS Exchange, hyperMILL® and hyperCAD®-S Boast Improved CAD Data Access and Reuse, While Maintaining PMI and Data Integrity Needham, MA U.S.A. (August 17, 2020) – OPEN MIND Technologies AG, a leading developer of CAD/CAM software solutions worldwide, and Tech Soft 3D, the leading provider of engineering software development toolkits, announced that HOOPS Exchange, the industry’s...

Read More »OPEN MIND Technologies Celebrates 25 Years of CAM Software Leadership

Needham, MA U.S.A. (August 29, 2019) – OPEN MIND Technologies AG, a leading developer of CAD/CAM software solutions worldwide, announced it is celebrating its 25th company anniversary this year. Founded in 1994 and growing from just 20 employees to over 300 personnel located throughout the world in sales and service subsidiaries in 15 countries, OPEN MIND's hyperMILL® software suite is one of...

Read More »

New hyperMILL 2019.2 CAD/CAM Software Enables More Secure Programming with Reduced Process Time

Features include high-precision 3D finishing, 5-axis tangent machining, high-performance turning, and CAD-for-CAM technologies. Utilities streamline CAM programming and provide tested and proven methodologies. Multiple faces can be joined into one face with controlled ISO orientation.

Read More »

New Advanced hyperMILL CAM Software Offers Three Modules for Finishing, Roughing and Drilling

Enables the use of conical barrel cutter technology to reduce cycle times over 90%. Calculates toolpaths independently of machine and controller. Ideal for planar, ruled and curved surfaces found in complex 5-Axis components.

Read More »OPEN MIND/ hyperMILL-® Announces Joint 5-Axis Machining Technology Seminar with Grob Systems

Needham, MA U.S.A. (April 24, 2019) – OPEN MIND Technologies USA, a leading developer of CAD/CAM software solutions worldwide, has announced a joint 5-Axis Machining Technology Seminar with GROB Systems, a manufacturer of universal machining centers. On June 4, 2019 from 8:00 a.m. to 3:30 p.m., OPEN MIND and GROB Systems will offer a complimentary 5-Axis Technology Seminar in Auburn, Washington...

Read More »Open Mind Technologies Announces New hyperMILL Reseller for Texas, Louisiana

NEEDHAM, MA U.S.A. (April 5, 2019) – OPEN MIND Technologies USA, Inc., a leading developer of CAD/CAM software solutions, has announced that it recently partnered with a new authorized reseller, 5 Cell Technologies, located in Houston, Texas. 5 Cell Technologies will offer industry leading hyperMILL® CAM software from OPEN MIND in Texas and Louisiana, with a strong focus on 5-axis milling and...

Read More »Open Mind Announces New Partnership with Okuma, Joining Partners in THINC

NEEDHAM, MA U.S.A. (August 13, 2018) – OPEN MIND Technologies AG , a leading developer of CAD/CAM software solutions worldwide, has announced it has recently partnered with Okuma America Corporation, joining the Partners in THINC collaboration, founded by Okuma. OPEN MIND's strong focus on CAM, and its continued commitment to the latest technologies, produces trend-setting innovations that make...

Read More »OPEN MIND's hyperMILL-® CAM Solution Certified by Autodesk

From design to machining Wessling (Germany) – hyperMILLÃ-®, the CAM solution from OPEN MIND Technologies AG, is fully compatible with Autodesk Inventor, as officially confirmed once more following certification by Autodesk Inc. for hyperMILLÃ-® and the latest release of Autodesk Inventor 2014. The seamless integration of hyperMILLÃ-®, including data associativity, allows continuous...

Read More »OPEN MIND Technologies at Tire Technology Expo 2014

hyperMILLÃ-® tire module push machines to the limit Wessling (Germany) — OPEN MIND Technologies AG, one of the leading CAD/CAM software developers, is set to present its solutions for the tire industry at Booth 4050 at Tire Technology Expo 2014 in Cologne, Germany, from 11 to 13 February 2014. The tire module was once again significantly extended in the current version of the...

Read More »

OPEN MIND Extends Partnership with PTC-®

Wessling, Germany, June 4, 2007 - hyperMILLÃ-®, the user-friendly 2-D, 3-D, HSC, and 5-X CAM system, is now available integrated within Pro/ENGINEER Wildfire from Parametric Technologies Corp. As OPEN MIND Technologies AG has recently renewed its membership in the PTC Partner Advantage(TM) Program, this partnership makes OPEN MIND's technology-leading hyperMILL software available to...

Read More »