CAM Software features automatic collision avoidance.

Share:

Press Release Summary:

HyperMILL® v9 multi-axis CAM software provides functions that include stock roughing with automatic feedrate reduction, stock management, definition of milling and stop surfaces, and machine and material removal simulation. Feature technology aids in processing existing machining and geometry information to minimize required programming in CAM system. Bidirectionality between CAD model and feature list enables features to be identified via feature list or in CAD model.

Original Press Release:

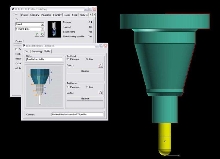

Feature Technology and Automatic Collision Avoidance Highlight hyperMILL® V9 from Open Mind Technologies USA

hyperMILL® V9 multi-axis CAM software from OPEN MIND Technologies USA (Wellesley Hills, MA) comes with a wide range of new functions that reduce programming requirements and optimize machining both on a large and a small scale. These functions include improved stock roughing with automatic feedrate reduction for full cutting and path optimization in axis-parallel machining, stock management, easy definition of milling and stop surfaces, and machine and material removal simulation. By far, the most impressive function for optimizing work processes is the greatly improved feature technology.

Fully developed feature technology represents the ideal way to efficiently process existing machining and geometry information and thus clearly reduce the amount of programming required in the CAM system. This means hyperMILL V9 automatically recognizes and processes geometry information from surface and solid models. Feature recognition takes place on the whole model, recognizing holes and other geometries including pockets and plane levels and storing the features in a feature list. Complex machining sequences, in the form of technology macros, can then be assigned to these features. This provides a range of intelligent and automated functions to support programmers.

Another important feature is bidirectionality between the CAD model and the feature list, meaning features can be identified via the feature list or in the CAD model. Sorting and filter functions including type, orientation, color, layer, or parameters such as drilling depth and diameter make it possible to precisely search for the features to be processed. Current model status, including visible elements, orientation and zoom, can be saved and activated for any feature at any time. Locating smaller geometries, in particular, is now much easier.

New stock tracking with various tool orientations

Enhanced stock-tracking in hyperMILL V9 guarantees an unprecedented amount of control of machining status. This allows the user to calculate, as required, current machining status for every job step, any number of selected job steps, or for the entire job. The stock model management can also work with many jobs that have different tool orientations, or with multi-axis machining. Stock management takes place in a separate job list window. This provides a clear display of the stock already calculated. Calculated stock is suitable for visual feedback or as a basis for further machining such as the roughing of any stock.

The range of functions for roughing any stock has also been greatly expanded. This cycle now includes automatic plane-level recognition. This functionality ensures uniform allowances for subsequent finishing or enables surfaces to be completely machined at the roughing stage. Used in conjunction with stock tracking, this cycle makes the roughing of parts with thin-walled ribs (typical of aerospace parts) much more efficient. The bottom can be processed in one machining cycle, while material remains on the walls for subsequent finishing.

Drilling now includes a retract plane-checking process. In practice, this means every movement can now be checked for collision with the model. Thus clearance planes within some drilling templates can be placed very close to the part being machined, reducing air time to a minimum. In addition, it is also possible to define retract planes between individual drilling templates with various tool positions. As movements between individual machining planes and infeed movements between drill points are both checked for collision with the model, this cycle includes a particularly reliable collision check. If a collision is detected, the cycle automatically repositions to a collision-free plane.

Faster collision control and avoidance

Collision control and avoidance is especially important for 5-axis machining; however, it is also important for many 3D applications as well. Collision control in hyperMILL® V9 is now much more powerful for two reasons. The first is that tool heads and holders can now be freely defined. The generated rotational solid is included in the collision control and avoidance. Moreover, the rotational solid is managed in the tool database and is always available once defined. The other reason is that the computation time is considerably reduced for the collision-check process despite utilizing more detailed data on tools and holders. All in all, performance is increased considerably.

About hyperMILL

hyperMILL offers the broadest set of indexing, incrementing, and multi-axis simultaneous cycle options on the market. OPEN MIND offers a set of technology steps that allow each user to select operations that match their application need and machine tool capability. Some of the basic steps include 3d machining [still used for most roughing material removal], traditional indexing with arbitrary workframes, and Advanced Indexing that provides traditional Z-axis cutter paths, with an arbitrary workframe and with full interference checking.

hyperMILL also has many multi-axis simultaneous strategies for high-performance machine tools. Some of these are based on surface parameters [drilling, swarf milling, and top milling] and others use independent guide curves or surface offsets to influence the cutter orientation distribution.

The manufacturing industry needs to be able to respond quickly to the demands of customers, while keeping costs as low as possible. hyperMILL® V9 is the perfect tool for achieving this balance. Fully developed feature technology and numerous new automated functions guarantee more efficient and time-saving operations.

About OPEN MIND Technologies AG

OPEN MIND Technologies AG is a leading developer of CAD/CAM solutions for designing and manufacturing complex moulds and parts. OPEN MIND offers an extensive range of products from feature-oriented solutions for milling standard parts through to software for 5-axis simultaneous machining. With over 6,000 licences sold across the automotive, tool and mold manufacturing, mechanical engineering,and aerospace industries, OPEN MIND Technologies AG is represented in all the important markets in Asia, Europe and the US.

For further information, contact

OPEN MIND Technologies USA, Inc.

Alan Levine

70 Walnut Street

Wellesley Hills MA 02481

Tel.: (781) 239 8095

Fax: (270) 912 5822

Sales.Americas@openmind-tech.com

www openmind-tech.com

Ray Chalmers or Ron Curcuru

G. Temple Associates

r.chalmers@gtemple.com