Key Technology, Inc.

Walla Walla, WA 99362

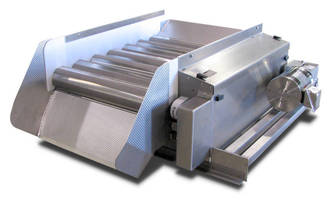

Monobeam Vibratory Conveyors support food processing.

With frame made of single structural member, Iso-FloÃ-® Vibratory Conveyors offer optimized hygiene, minimizing risk of product contamination and maintaining food safety. Frame and spring arms can be tucked completely under conveyor bed. Featuring standard rotary polish within product contact zone, stainless steel bed resists bacterial attachment and biofilm formation. Standard oil-free...

Read More »

Optyx Sorters Maximize Product Quality at Tayto

Tayto is the largest British-owned manufacturer of potato chips/crisps and the top selling brand of chips in Northern Ireland. Their mission is to make superior products by using superior technology. In 2014, they turned to Key Technology and installed four new OptyxÃ-® digital sorters to better control the removal of defects and foreign material (FM) and produce the highest quality...

Read More »

Key Technology Exhibits New VitiSort(TM) Wine Grape Optical Sorter for MOG Removal at Unified Wine Symposium

Key Technology's VitiSort Key Technology will exhibit VitiSort™, a new optical sorter for red wine grapes, at its Unified Wine Symposium booth #1917. VitiSort combines a patent-pending mechanical MOG (material other than grape) removal shaker and optical sorting with an integral juice recovery system on one compact system to achieve world-class sorting performance at a unique level of...

Read More »

Optical Sorters feature software-driven intelligence.

Available for MantaÃ-®, OptyxÃ-®, and TegraÃ-® belt-driven G6 optical sorters, Sort-to-Grade™ feature for potato processors enables sorters to grade by count, accepting or rejecting each defective piece to control quality of output to defined grade, as defined by processor.Ã- By reducing unnecessary rejects, software increases yield 1–3%. Sorting foreign material remains...

Read More »

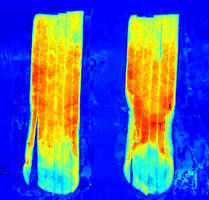

Key Technology Unveils New State-of-the-Art Product Definer

Hyperspectral image of sugar end potato strips, as captured by Key Technology’s Product Definer, aids in designing new sorting systems that solve outstanding product quality problems Key Technology unveils its new Product Definer, a state-of-the-art instrument, located in its customer visitor center. This proprietary hyperspectral imaging spectrometer helps Key quickly analyze and evaluate new...

Read More »Online Training from Key Technology Delivers Value to a Multinational Food Processor

Recently, a major multinational food processor was searching for new optical sorter technology to improve their product quality and food safety, and evaluated several suppliers. After a thorough analysis, the processor selected Key Technology and installed Key's high-volume Manta-® sorter and lower-volume Optyx-® sorter. Both sorters feature cameras and lasers to maximize the detection and...

Read More »

Flume Wash is designed for fresh-cut produce.

Suited for small to medium-large processors producing variety of products such as shredded, chopped, and whole leaf lettuce, cabbage, and baby spinach, Flume Wash gently removes heavy debris, silt, grubs, and floating contaminates. It handles up to 3,000 kg of leafy product or 7,000 kg of fruits or vegetables/hr. Featuring self-cleaning parabolic filter, heavy-duty pump motor, Iso-Flo-®...

Read More »

Basket Washer handles fresh-cut produce.

Featuring sanitary tank that holds 145 gal of water, semi-automatic Basket Wash is suited for small to medium-large processors handling up to 3,300 lb of produce/hr. Closed-loop water system recycles and filters water, flushing baskets of produce with up to 175 gal of water/min, removing debris and minimizing bacteria content. Wash cycle time can be adjusted via Allen-Bradley controller. Basket...

Read More »

Packaging Machine consistently seals fresh-cut produce bags.

Featuring semi-automatic, push-button operation, AV Sealer heat-seals various bag sizes with or without vacuum and has optional gas flush cycle. Adjustable user programs set vacuum pressure, gas flush, heat sealing temperature, and seal time. Able to be switched over to handle different products and bag sizes in seconds without tools, changeparts, or mechanical adjustments, PLC-controlled unit...

Read More »Key Technology Appoints John Dykstra as Director of Service Operations â Americas & Asia Pacific

December 1, 2020 – Key Technology, a member of the Duravant family of operating companies, announces the appointment of John Dykstra as Director of Service Operations for North America, South America and the Asia-Pacific region. Dykstra is responsible for overseeing Duravant’s SupportPro aftermarket services at Key to help customers operate and maintain their digital sorters, specialized...

Read More »Key Technology and Heat and Control Form Strategic Partnership in South Africa and Sub-Saharan

November 10, 2020 – Key Technology, Inc., a member of the Duravant family of operating companies, and Heat and Control Pty Ltd. announce an extension of their existing strategic partnership, supporting customers in Australia, New Zealand and India, to now include the region of South Africa and Sub-Saharan. Under the terms of the agreement, Key has appointed Heat and Control as their exclusive...

Read More »Key Technology Promotes Quentin Kemph as Area Sales Manager for The South Central United States

March 11, 2020 – Key Technology, a member of the Duravant family of operating companies, announces the promotion of Quentin Kemph as Area Sales Manager for the South Central United States. Kemph is responsible for bringing Key’s high performance digital sorting, conveying and other automation systems to customers that process fruits, vegetables, potatoes, nuts, snack foods, poultry and more....

Read More »Key Technology Acquires Herbert Solutions, a Renowned Supplier of Sorting and Processing Equipment for Root Crops

January 8, 2020 – Key Technology, a leading global designer and manufacturer of digital sorting, inspection, conveying and other processing equipment, and a member of the Duravant family of operating companies, has acquired Herbert Solutions, enhancing its portfolio of potato and vegetable equipment solutions. Herbert has established itself as a leader in serving the root crop and fresh...

Read More »Key Technology Expands Its Customer Service Offerings With SupportPro

December 17, 2019 – Key Technology, a member of the Duravant family of operating companies, announces the rebranding of its customer service organization as SupportPro. This global program includes technical support such as installation, start-up, training, preventive maintenance and 24/7 emergency assistance as well as remote monitoring, protection plans, upgrades and parts sales, and other...

Read More »Key Technology Promotes Daniel Leighty To Global Vice President of Sales

October 29, 2019 – Key Technology, a member of the Duravant family of operating companies, announces the promotion of Daniel Leighty to Global Vice President of Sales. Leighty is responsible for activities that lead Key’s worldwide sales organization to bring the company’s high performance digital sorting, conveying and process automation systems to the market. “During his 12 years with...

Read More »Key Technology Celebrates 70 Years of Innovation

August 23, 2018 – Key Technology, a member of the Duravant family of operating companies, is celebrating their 70th anniversary. Since introducing their first automated food processing system in 1948, Key has grown to become a global leader based on the principles of innovation, reliability and superior customer service. Today, Key’s digital sorters, vibratory conveyors and other automation...

Read More »Key Technology and Heat and Control Form Strategic Partnership in Australia, New Zealand and India

August 21, 2018 – Key Technology, Inc., a member of the Duravant family of operating companies, and Heat and Control Pty Ltd. announced that they have entered into a strategic partnership to support customers in Australia, New Zealand and India. Under the terms of the agreement, Key has appointed Heat and Control as their exclusive agent to sell and service Key’s high performance digital...

Read More »Key Technology Appoints Alvaro Nunez as Area Sales Manager for Central and Northern California

July 17, 2018 – Key Technology, a member of the Duravant family of operating companies, announces the promotion of Alvaro Nunez as Area Sales Manager for Central and Northern California. Nunez is responsible for bringing Key’s high performance digital sorters, vibratory conveying solutions and other automation systems to food processors and other manufacturers. Nunez is based out of...

Read More »Key Technology Appoints Bret Larreau as Director of Latin America and Asia Sales

July 12, 2018 – Key Technology, a member of the Duravant family of operating companies, announces the promotion of Bret Larreau to the position of Director of Latin America and Asia Sales. Larreau is responsible for managing Key’s sales activities in the Latin America, Asia Pacific and Australia/New Zealand regions to bring the company’s digital sorters, vibratory conveyors and other...

Read More »