Weld Head handles return bends in thin walled tube.

Using Orbital Welding Power Supply, Model M45 enables welding of thin-walled return bends to tubes fitted into heating and cooling equipment. Rotation of torch is consistent, and delivery of welding current is kept constant and can be varied around circumference of tube. Suited for welding stainless steel, nickel alloys, and titanium tubes from 6-20 mm OD, head is controlled with closed loop...

Read More »TIG Welding Head suits tube to tubesheet applications.

Suited for high production environments where fusion weld is suitable, automatic TIG welding head, Model P24 accommodates tube diameters from 10-26 mm. It clamps directly to tube to be welded via expanding mandrel, which is operated by mechanical clamping system. As clamping mechanism clamps inside tube, head is automatically aligned concentrically. Fully enclosed welding zone enables unit to be...

Read More »

Orbital TIG Weld Heads use on-board wire feed system.

ORBIWELD TP Series covers range of tube and pipes from 10-275 mm OD. Models TP600 and TP1000 handle pipe diameters up to 170 mm and 275 mm, respectively. Both heads can be used with or without wire feed units. Drive mechanism of arc gap compensation mechanism ensures consistent profile around circumference of tube. Compact, lightweight design facilitates handling and use.

Read More »

Weld Heads suit limited access applications.

Designed for welding closely packed stainless steel tubes and fittings in pipeline systems, Orbiweld S series slim line weld heads feature quick fit Snap In collet system. Design incorporates water cooling channels around weld head body, and all main process functions are controlled on in-handle panel. Suited for on-site use, applications include electronics, offshore, pharmaceutical, and...

Read More »

Top 10 Industries That Benefit From Water Treatment Solutions

Learn about which industries benefit the most from water treatment solutions.

Read More »

Weld Head targets applications with low radial clearance.

Water-cooled, Model M34 covers tubes with OD from 12-46 mm and works with welding currents up to 200 A. It includes onboard wire feed unit and arc gap control mechanism, which takes into account any ovality in tube profile. Torch angle and wire entry angle can be adjusted to suit weld preparation and joint profile. Model M34 is suited for fusion-only welds as well as applications that require...

Read More »

Orbital Weld Heads weld pipe in place.

Redhead weld heads, used with digital Tubemaster Power Source, are designed for orbital welding of pipe/tubes from 0.5-6.625 in. Products can be used for autogenous welding applications or with optional wire feeder. Mechanical device maintains constant arc length on out-of-round pipes, and design incorporates continuously adjustable clamping. Weld heads mount on one side of weld joint, allowing...

Read More »

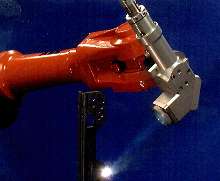

Focus Heads suit welding and heat treatment applications.

Luminator(TM) heads are based on 1-piece machined body, sealed to industrial standard IP55 for work in demanding conditions. Straight and right-angle forms are available with CCTV option available for right-angle version. Basic head accepts ancillary items such as air knives and welding gas nozzles. Precision fixing points allow repeatable mounting on robots and other processing equipment.

Read More »

Weld Head suits limited-clearance applications.

Orbital Model 8 Series, for fusion TIG applications, welds tube and thin-wall pipe from 0.25-6.625 in. OD. When connected to cooling unit, all components are liquid cooled, including cables, clamp housings, and electrode rotor. Narrow width of head makes it suitable for applications such as welding fitting-to-fitting or fitting-to-valve body assemblies, and welding materials such as stainless...

Read More »

Weld Heads allow welding of pipes and tubes in place.

Quickclamp Weld Heads are designed for GTAW circumferential butt welding of pipes and tubes. They cover size range from 1 in. OD tube to 6 in. pipe. Units include electronic Arc Gap Control, filler wire feed capability, torch rotation, and torch oscillation with adjustable stroke width, speed, and end point dwell. Heads mount using adjustable clamp. Standard 2 lb wire spool, mounted directly on...

Read More »

Weld Head provides high purity welding of micro-fittings.

UHP Mini-Micro(TM) Orbital Weld Head can be used to weld micro-fittings and tubing from 1/8 to 1/2 in. OD. Water-cooled design ensures long-term operation at 100% duty cycle with no damage to head. Unit features vise clamping tool steel jaws and narrow profile. Weld heads up to 6 in. OD are also available.

Read More »

Dodge® Raptor Coupling Now Available in Three Larger Sizes

The Dodge Raptor coupling epitomizes the innovation and value that has made Baldor a world leader in industrial electric motors. For almost 100 years Baldor has been the go-to source for industries across the globe. The Raptor coupling is just one example of our dedication to engineered excellence and commitment to providing value and performance. See our video to learn more.

Read More »