Terberg Matec UK Ltd, Futuresource 2010 Preview

Terberg Matec UK Ltd. return to Futuresource with additional stand space for 2010 aiming to build on the success of last years show. Silver Zone stands M20 and N20 are set to showcase new and exciting innovations from Terberg's diverse product portfolio, in particular, stand M20 will represent a very different product from the Terberg design team in the shape of the KTZ Underground and...

Read More »

Automated Mixing, Blending and Transfer Systems Ensure Product Purity, Process Protocol and Worker Safety

Custom software controls, manages and validates system-wide process and safety operations for each bin Ft. Worth, TX: Mixing, blending and transfer systems designed, engineered and custom programmed in-house by Tote-® Systems provide seamless and automatic control for processing and reporting on dispensing, mixing, blending, filling and transport operations involving pharmaceutical powders,...

Read More »Neptune E1000 Electronic Register

ITRON Greenwood SC announced the Neptune E1000 electronic register has received National Conference on Weights and Measures approval for custody transfer of LPG (NCWM certificate number 09-064). E1000 Features and Benefits: Direct retrofit to RL100 dispensers with 600 series adaptor Displays volume or flow rate Automatic reset with programmable time out between deliveries Measures gallons,...

Read More »Bulk Supply Systems transfer sealants and adhesives.

Featuring NXT air motor, small ram bulk supply systems transfer sealants and adhesives from 5, 7 and 16 gal containers. Graco L20c supply system suits low-volume applications of low-viscosity materials not requiring extra pressure, while Graco S20 is designed for low-volume in-plant applications of medium to high-viscosity materials. Models come with Graco Check-MateÃ-® pumps featuring...

Read More »

Caps & Plugs Designed for Peace of Mind

Download this engineering guide to learn more about the different caps and plugs offered, and to find the correct solution for your specific application.

Read More »

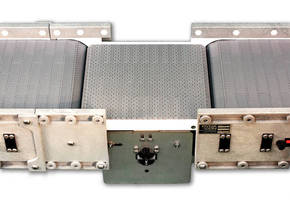

Powered Transfer provides alternative to roller transfers,.

With ability to transfer products of 2 in. from conveyor to conveyor, DynaCon powered transfer features plastic link style chain to provide base for product transitions, by reducing gap between conveyors to 1Ã-½ in. They offer slider bed length of 12 in. with widths available from 4-36 in. Single and variable speed motors are available with speeds up to 100 ft/min. Available with 2 belting...

Read More »

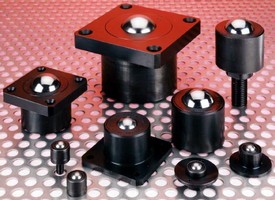

Serving as Alternatives to Carts or Casters

Uniquely designed versions of Euro ball transfer units from SKF-® feature integral spring clips to enable quicker installation on floors or other surfaces. The clips eliminate any need for fasteners, loose hardware, or fixing holes. When installed, the ball transfers can serve as practical and durable alternatives to carts and casters by creating a ready-made surface over which materials can...

Read More »MonetaExpress Selects Cyphermint as Mobile Payment Technology Provider

Marlborough, MA-June 20, 2007- Cyphermint, Inc., a leading provider of secure electronic payment solutions, announced today that they have entered into an agreement with Moneta Express Corp., a leader in international remittances processing and services, to provide mobile online financial services using Cyphermint's PayCash Mobile(TM) technology. The agreement between Cyphermint and MonetaExpress...

Read More »

Spring-Loaded Ball Transfers have self-adjusting design.

SKF-® Hevi-Load spring-loaded ball transfer units are engineered to reduce damage caused by shock loads, allow for dimension changes due to temperature, and self-adjust for even load distribution. Recirculating ball system offers capability to handle load capacities to 4,400 lb, with ball either up or down. It employs 12.7-50.8 mm dia load ball that rotates on bed of small balls supported on...

Read More »

Ball Transfer Units suit air cargo handling systems.

Incorporating 30 mm load balls with load ratings up to 771 lb/unit, Heavy Duty 806 ball transfer units can be accessed for cleaning or parts replacement. Features include solid steel machined housings and tops that protect against impact damage, and self-cleaning slotted exit hole to filter large debris particles. Units can be supplied with steel bearings and zinc-plated components, stainless...

Read More »Load Transfer Stations offer various positioning abilities.

Load Transfer Stations are available with multiple load positioning capabilities that enable transfer of loads that need to be inset, overhung, or flush with edge of go-to pallet. Addition provides inset or overhang up to 1.5 in., enabling users to keep loads centered during pallet exchange. Offered on any stand-alone or fully integrated pallet exchange system, capabilities help optimize lift...

Read More »

Optimize Your Storage or Distribution Facility with Steel King Rack Solutions

Steel King racks are designed to meet seismic requirements in the most demanding conditions. Our durable storage products help your company save on maintenance costs. Check out our product video or download our Rack Planning eBook to learn more.

Read More »