DMI Event to Highlight Mazak Innovations that Boost Job Shop Efficiency

FLORENCE, Ky.,Ã- – Mazak distributor Dependable Machine Inc. (DMI) will host an open house at its new technology center in Hayden, Idaho, May 10-12 from 10:00 a.m. – 4:00 p.m. (PDT). The event will feature Mazak technologies that simplify part production processes as well as enhance shop floor productivity and versatility. A must-see for attendees will be Mazak’s MAZATROL SmoothX CNC....

Read More »

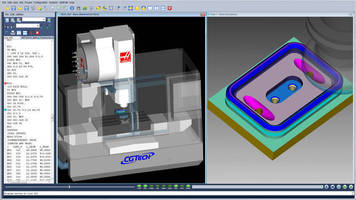

VERICUT Helps Grade Turning and Milling SkillsUSA/NIMS Contest Submissions

Irvine, CAÃ- - CGTech will be on hand at the National Leadership and Skills Conference (NLSC), June 21-23, 2016, to help grade multiple SkillsUSA/NIMS events related to Computer Numeric Control (CNC) machining. CGTech will also be exhibiting its latest version of VERICUT software in Booth S149. More than 16,000 peopleÃ- - including students, teachers and business partnersÃ- - will be...

Read More »Desktop CNC Tool uses standard 120 V power.

With 36 x 24 in. work area, ShopBot Desktop MAX can fit items such as guitars,Ã- chair and table parts, and cabinetry parts. Tool is used in prototyping and full production for cutting, carving, machining, and milling in wood, MDF, plastics, foams, and non-ferrous metals. Featuring dual-motor gantry design, tool offers 2 options for beds: aluminum deck or plenum with universal hold-down...

Read More »

Mazak Presents its HYBRID Approach to Additive Manufacturing at RAPID

Company combines additive and subtractive processes with multi-tasking part processing FLORENCE, Ky.Ã- - Mazak firmly established its position at the forefront of additive manufacturing with the development of HYBRID Multi-Tasking technology, which the company will present at this year’s RAPID Conference and Expo. The event takes place at the Orange County Convention Center in Orlando,...

Read More »

Understanding Food & Beverage Lubricants

The term "food-grade lubricants" may sound like another name for food oils such as cooking spray, salad dressing, lard, or canola oil, but it actually refers to lubricants that are safe for use in food processing equipment.

Read More »

Mazak to Spotlight Accurate, Affordable Milling and Turning Solutions at TECMA

FLORENCE, Ky. –Ã- At TECMA 2015, taking place March 3Ã- - 6 in Mexico City, Mazak will spotlight accurate, affordable machine tools in Stand 430 that will forever change how machine shops process small and medium-sized workpieces for a variety of industries. During the show, Mazak will run part cutting demonstrations on the VERTICAL CENTER UNIVERSAL 400A 5X, VERTICAL CENTER NEXUS 510 5X...

Read More »

GMTA News of Note

Ann Arbor, Michigan – GMTA (German Machine Tools of America) represents various top-quality German metalworking machine builders, including Wera Profilator, K + G, Pittler, Praewema and WMZ, as well as Arnold lasers and Rosink parts washers.Ã- These machines are sold to the North American market exclusively by GMTA, primarily for gear and spline production, as well as other power...

Read More »

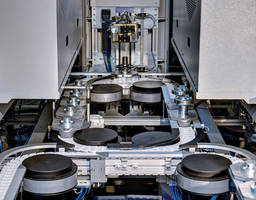

Vertical Turning DUO Cell

The machining concept of vertical pick-up machines as a modular system meets manufacturing companies' requirements for more quality, while simultaneously maintaining high flexibility and reducing cost. The right-hand and left-hand versions of the EMCO Maier VT 160 and VT 250, when linked with one of three basic conveyor options -- oval, meander, and crossover-meander designs -- provide a complete...

Read More »

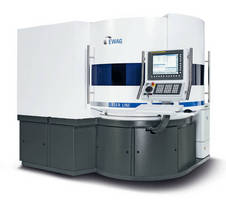

UNITED GRINDING's Vast, Advanced Technology to Stand Out at GrindTec 2014

Company to display several new innovations from WALTER, EWAG and STUDER in Hall 7-7050Ã- MIAMISBURG, Ohio – UNITED GRINDING, the largest single-source provider of complete and integrated grinding solutions, will showcase its latest grinding, eroding, laser and measuring innovations for general purpose and advanced tool and cutter production in Hall 7-7050 at GrindTec, taking place March 19...

Read More »

Nanotech Demonstrates Most Flexible Diamond Turning System

During SPIE Photonics West 2014 in San Francisco, Nanotech will demonstrate what has become their true flagship machining system. The Nanotech 350FG is the most diverse ultra-precision machine available. Starting with a minimum of three ultra- precision axes, it is easily expandable to five axes via optional B & C rotary axes. Typical applications for this machine include axisymmetric machining...

Read More »

Pipe Beveling Tool End preps offshore piping systems.

Designed for dry-cutting high-temperature, high-pressure pipe from 4.5–18 in. OD, MILLHOGÃ-® Dictator Welding End Prep Tool features 3 hp air motor designed for operation in environments that have dirty air and high moisture content. ID clamping pipe milling machine develops 4,100 lb-ft torque at cutter blade and pulls continuous thick chips without cutting oils. TiN-coated blades dissipate...

Read More »

Dies & Stamping Services with Over 25 Years of Experience

PDS is an established leader in progressive die stamping, with a reputation for providing precision and value that dates back more than half a century. Through extensive capabilities and a staff of seasoned professionals, we set the standard for quality, delivering flexible services that can meet the needs of the most challenging requirements. See our video to learn more.

Read More »