Graphite Adhesive withstands high temperature cycling.

Press Release Summary:

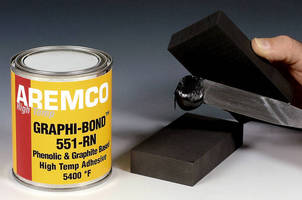

As single-part, phenolic-bonded, graphite-based, and fiber-reinforced adhesive, Graphi-Bond™ 551-RN may be used to bond, fill, and repair carbon-carbon and graphite components and fixtures used in reducing atmospheres to 5,400°F. Coefficient of thermal expansion, 4.1 ppm x 10-6/°F, matches most grades of carbon and graphite. After setting at room temperature for 1–2 hr and curing at 265°F for 2–4 hr, material demonstrates moisture resistance and tensile-shear strength in range of 1,100 psi.

Original Press Release:

Graphi-Bond 551-RN High Temp Graphite Adhesive Now Available

SUMMARY

Graphi-Bondtm 551-RN, a new single part, high temperature, graphite-based adhesive manufactured by Aremco Products, Inc., is now used to bond, fill and repair carbon-carbon and graphite components and fixtures used in reducing atmospheres to 5400 ºF (2980 ºC).

FEATURES

Graphi-Bondtm 551-RN is a single part, phenolic-bonded, graphite and fiber-reinforced, high temperature adhesive used to bond, fill and repair carbon-carbon and graphite components and structures used in reducing atmospheres to 5400 ºF (2980 ºC).

Graphi-Bondtm 551-RN is used typically to bond and patch carbon-carbon and graphite components such as brushes, RF susceptors, fixtures, electrodes, crucibles, furnace parts, metal-casting dies, and continuous casting dies. Due to its low coefficient of thermal expansion, 4.1 ppm x 10-6/ºF, which matches most grades of carbon and graphite, it is ideal for thermal cycling applications.

Graphi-Bondtm 551-RN is an easy-to-apply, dispensable adhesive that contains no asbestos or volatile organic compounds. After setting at room temperature for 1-2 hours and curing at 265 oF (130 oC) for 2-4 hours, it demonstrates exceptional moisture resistance and tensile-shear strength in the range of 1100 psi.

Graphi-Bondtm 551-RN is available from stock in pint, quart, gallon, and five-gallon pails. Please contact Aremco’s Technical Sales Department for more information about this advanced product.